The goal of this technote is to identify the hazards posed by different types of paint strippers and also offer laser cleaning as an alternative healthy and green solution that can replace it.

The principle of use of paint strippers are simply to apply the paint stripper to the painted surface, wait for few minutes for some chemical reactions to take place between the paint stripper and the paint and finally scratch the paint off. Figure 1 shows the application of paint stripper and its subsequent removal

Figure 1: Removal of paint after application of paint stripper

Chemical paint strippers contribute to environmental pollution because they emit Volatile Organic Compounds (VOCs) and produce lot of secondary waste that needs to be cleaned up. Exposure to the chemical ingredients may cause chronic health effects and that’s why personnel working with paint strippers need to wear Personal Protective Equipment (PPE) as shown in Figure 2

Figure 2: Protective gear required to be worn by personnel working with paint strippers

In addition the high amount of toxic waste that is generated needs to be disposed safely. The process is quite labour intensive as well and can’t be automated.

Several different types of paint strippers are used for removing paint but they can be mostly classified into two categories, flammable and non-flammable types. Each of these types of paint strippers have some pros and cons which will be described in detail but what is common between the two types is the danger to the health by breathing the toxic vapours they emit and also the fact that they are carcinogenic [Reference 1].

Inflammable type:

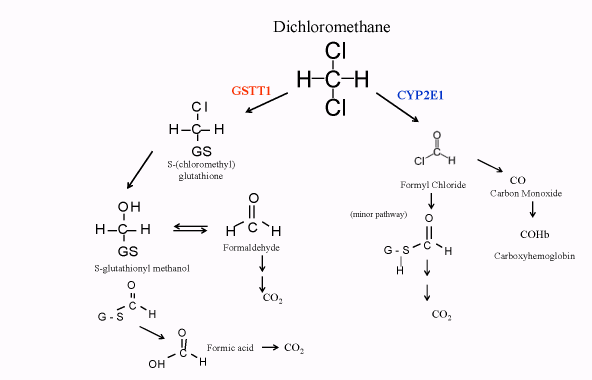

The inflammable type mostly contains methylene chloride or otherwise known as di-chloro-methane (DCM, CH2CL2). Environmental Protection Agency (EPA) has classified this material as carcinogenic. Also it is known that after chemical reaction with paint, DCM produces carbon monoxide which is quite dangerous for breathing and could cause suffocation. The conversion of carbon monoxide to carboxyl hemoglobin in the blood is quite dangerous for the body and may cause suffocation and heart issues. Figure 3 shows the possible mechanisms of conversion of Di-Chloro-methane to carboxyl hemoglobin

Figure 3: Mechanism of conversion of DCM to carboxyhemoglobin [Reference 2]

Methylene chloride is non-flammable but it is highly recommended to use this paint stripper either outdoors or if it needs to be used indoors, in a space where there is sufficient air circulation.

Flammable type (Acetone, Toluene and methanol)

Flammable types of paint strippers contain acetone, Toluene and methanol. Care has to be taken not to use these paint strippers in areas where there is a possibility for a spark such as in locations where furnaces have been installed.

Case studies for hazardous effects of Di-Chloro-Methane(DCM):

Several case studies have been performed on hazardous effects of DCM and one particular example is the case of a 66 year retired old man with no previous history of heart disease who chose to perform furniture refurbishing as a hobby [Reference 3]. He applied a paint stripper top the furniture and was working in the basement for 3 hours with a gas furnace located in it and not much of air circulation. Later on in the day he experienced severe chest pain and was admitted to the hospital. Several other case studies also show hazardous effect on healthy individuals.

Use of Laser for paint stripping:

An efficient, healthy and green alternative to sue of paint strippers is using a near IR fiber laser to strip the paint. The laser would generate a plasma which in turn creates a shock wave in the paint and blasts it into pieces and hence a clean removal of paint is performed. The ejected particles are collected by a vacuum pump right away and hence there are no danger of contamination of the environment. There are no consumables with laser technology and the operators do not need to wear operating gear except for a laser goggle to protect their eyes. The process can be automated which makes the process faster and more efficient. Table 1 compares different aspects of laser cleaning method to other methods including paint strippers (See Solvents)

| Cleaning Technique | Laser Cleaning | Dry Ice | Sand | Glass Beads | Walnut shells | water | Steam | Solvents |

| Waste for Disposal | Very low | NO | YES | YES | YES | YES | NO | YES |

| Abrasive | NO | NO | YES | YES | YES | NO | NO | YES |

| Toxic waste | Very low | NO | YES | YES | YES | NO | NO | NO |

| Electrically Conductive | NO | NO | NO | NO | NO | YES | YES | YES |

| Consumable needed | NO | YES | YES | YES | YES | YES | YES | YES |

| Other gear Required | NO | YES | YES | YES | YES | NO | YES | YES |

| Preparation Intensive | NO | NO | YES | YES | YES | YES | YES | YES |

| Environment-friendly | YES | (CO2) NO | NO | NO | NO | NO | NO | NO |

| Noisy | Very low | Very high | Very high | Very high | High | High | Medium | Low |

| Vibration | NO | YES | YES | YES | YES | YES | Medium | NO |

| Dry process | YES | YES | YES | YES | YES | NO | NO | NO |

| Hazardous | Low | High | Very high | Very high | Very high | high | high | Medium |

| Cause Airborne particles | NO | YES | YES | YES | YES | YES | YES | NO |

| At-line-online cleaning | YES | NO | NO | NO | NO | YES | NO | NO |

| Work on hot or cold surface | YES | sometime | YES | YES | YES | NO | YES | NO |

| Extra Nuzzel or tools to shape fflow | NO | YES | YES | YES | YES | YES | YES | NO |

| Performance Comparison | Excellente | Great | OK | OK | Limited | OK | Poor | Limited |

Table 1: Comparing laser cleaning method with other methods shows the great advantages of the former.

Laser cleaning requires careful selection of laser parameters such as pulse energy, repetition rate and wavelength of operation which should suit material properties. However, once this selection is done it is a much healthier and superior alternative to chemical paint strippers.

Laser paint stripping has been used in aviation industry [Reference 4], automobile industry [Reference 5], ship industry [Reference 6] and for bridge maintenance and repainting [Reference 7]. The selectivity, efficiency, controllability, environmentally friendly operation and operator safety have shown themselves in all of the above mentioned industries.

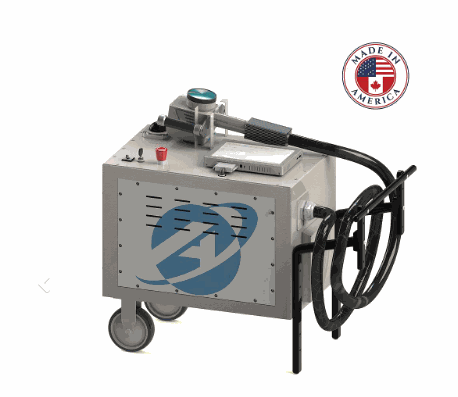

Allied Scientific Pro has developed such a laser cleaning system. Figure 4 shows the laser blast system where a fiber based near IR laser is used to remove paint

Figure 4: Laser blast system by Allied Scientific pr

The following link provides more information about ASP’s laser cleaning system:

https://lasercleaning. alliedscientificpro.com/

Allied Scientific Pro provides a 100 Watt and a 200 Watt laser cleaning system. The 200 Watt laser cleaning system has a faster paint stripping rate

References:

1- US consumer product safety commission report. What you should know about paint strippers.

2- EPA report: Toxicological report of Dichloromethane

3- Environmental medicine (Online book): Integrating a missing element into medical education (1995). Case study 24: methylene chloride toxicity.

4- https://www.industrial-lasers.com/ surface-treatment / article / 16485585 /applications -of-laser- coating-removal- technology , Application of laser coating removal technology

5- A review of incorporating Nd:YAG laser cleaning principle in automotive industry, Mohammad Khairul Azhar Abdul Razab et. Al, Journal of radiation research and applied sciences, 11, 2018.

6- High power fiber laser cleaning for green ship building, G.X. Chen et al., JLMN journal of micro/nano-engineering, vol 7, No 3, 2012.

7- https://www.laserax.com / blog / how- does-laser-cleaning-work, laser cleaning is of interest for various industrial processes.