Water cooled nuclear reactors that use the fission process for creating electricity need to be decommissioned after 30 to 40 years for safety purposes. During the decommissioning process, two targets have to be achieved. First the, recyclable metal that has been contaminated needs to be cleaned off from radioactive contamination so that it can be recycled for the next generation nuclear reactors. Secondly disposable material such as concrete needs to be cleaned off so it can be transferred to temporary repositories and later to be transferred to permanent geological repositories. Figure 1 shows a nuclear power plant in the process of nuclear decommissioning

Figure 1:Decommissioning of a nuclear power plant

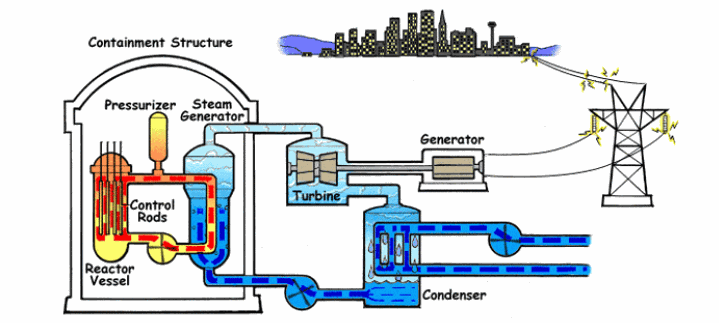

One has to understand the source of pollution in fission based nuclear power plants.

Figure 2: The general structure of a water based nuclear power plants [Reference 1]

One can describe the process of formation of the oxide layer in more detail as follows.

The same can be said about dry ice blasting as a decontamination technique with the difference that the ice pellets evaporate immediately and turn into CO2 gas which is a global warming gas and is therefore damaging to the environment.

In general, the current techniques and most common methods of decontamination of nuclear power plants are:

Wiping, dusting and flushing with water

Grit blasting

Dry ice blasting

Chemical cleaning

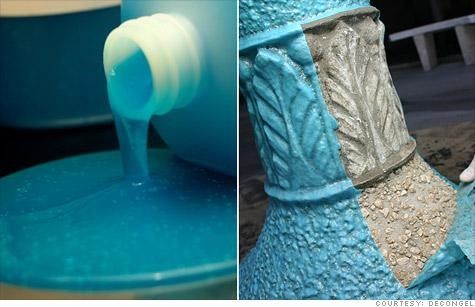

Decontamination by gel and foam

Some of these methods are shown in figure 3.

Figure 3: Clockwise from top: Decon by gel, wiping and dry ice blasting [References 2 and 3]

The main drawback of these methods are secondary radioactive waste that is generated and needs to be dealt with. In particular grit blasting process where sand particles are ejected from a high pressure nozzle can create a lot of secondary pollution and can also damage the structure or reduce the corrosion resistance.

An alternative most efficient method of cleaning if laser cleaning [Reference 1]. Fiber pulsed laser of few hundred watt power and nanosecond pulse width with repetition rates of few hundred kHz have been used to blast off the nuclear decontamination from pipes, metal tools and concrete blocks. The great advantages of laser cleaning are:

It is a process that can be automatized, so it increases cleaning speed

There is no secondary waste since all the debris are absorbed by a suction pump equipped with Hepa filter. So it is cleaner for the environment

Remote handling is possible so there is less exposure to workers.

Figure 4 shows laser cleaning in a nuclear environment with a 100 watt laser cleaning unit based on fiber laser developed by Allied Scientific Pro

Figure 4: Laser cleaning of a metal in a nuclear power plant

If one wants to mention a few disadvantage of laser cleaning, it would be the need to focus the beam and also the speed of operation which could be slower than sandblasting for example. However, the absence of secondary waste and possibility of automation and auto-focusing that makes the speed faster, outweighs these disadvantages and makes laser cleaning the method of choice for future cleaning.

Allied Scientific Pro offers laser cleaning systems of several power ranges. Theses include, 100, 200, 500, 1000 and 2000 Watt systems. For further information, refer to the following link.

https://lasercleaning. alliedscientificpro. com / laserblast /

References:

Laser decontamination and cleaning of metal surfaces, modelling and experimental studies, modelling and experimental studies, Anton Leontyev PhD thesis.

OPEC systems decon gel.