Different field applications for portable

near-IR spectrometers

(Diffuse reflection)

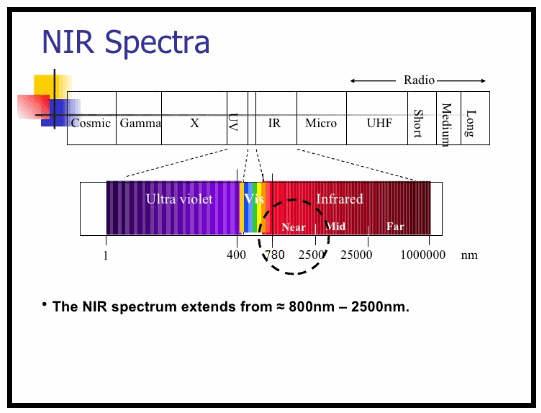

Near-IR spectroscopy was first discovered by William Herschel in 1800 when he observed that the region outside the dispersed visible spectrum near the red wavelength increased the temperature of a thermometer. Later he verified that the invisible rays also follow the properties of waves such as reflection, refraction, interference and diffraction. Near infrared is only a small section of the infrared light which also consists of mid-infrared and far infrared. The NIR spectral range can be defined as the region from 780 nm to 2500 nm or 4000-12820 cm-1. This can be compared to mid-infrared range which extends from 2.5 μm to 25 μm and far infrared range which covers the 25 c to 1 mm. This is shown in figure 1 below:

Figure 1: Position of near IR spectrum in the electromagnetic radiation

When light energy interacts with a material, energy is absorbed at resonant frequencies associated with atomic and molecular structure of the material. Molecular bonds are capable of stretching and bending and the absorbed resonance frequencies for these vibrations normally lie in the mid-IR region. These are the fundamental vibrations corresponding to stretching, bending, wagging and twisting in molecular bonds such as in C-C, C-O, C-N, C-H, O-H and N-H. Therefore the mid-infrared signal is very strong and absorption peaks are large. However, mid-IR is normally used for qualitative analysis for petro-chemicals, plastics and polymers which don’t contain too much water.

For quantitative analysis, normally the NIR region of light spectrum is used. The NIR region of the light spectrum mainly contains overtones and combination bands that are primarily attributed to hydrogen vibrations such as CH (fats, oil, hydrocarbon), OH (water, alcohol), NH (Protein). NIR spectra do not have the resolution of the mid-IR spectra and the signal levels are about 100 times weaker, however there are other advantages. For instance, NIR material can generally be collected off (diffused reflection) or through a material (transmission) without sample preparation which is required for MID-IR measurements. Also, NIR is suitable for measuring high and low water content material.

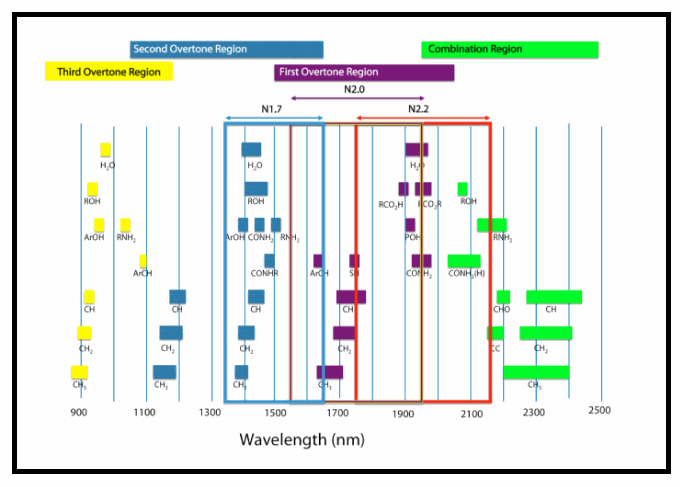

Figure 2 below shows the overtones and combination near–IR spectra.

Figure 2: Bonds and the corresponding wavelengths associated with near IR spectra

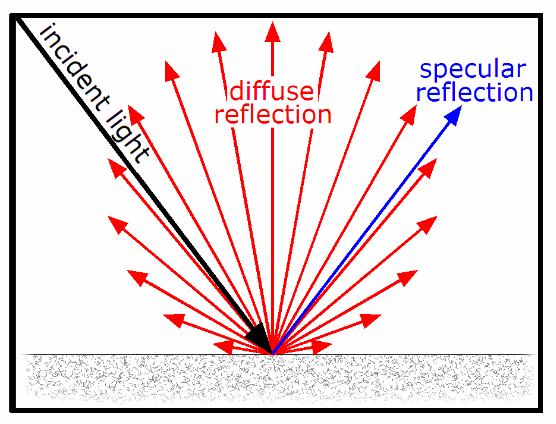

In order to collect the near infrared spectra several methods are used. These are trans-reflectance, in which the near infrared light beam penetrates the medium and also gets reflected by possibly seeds (780-1100 nm). Transmission is another mode where the light which has gone through the material is detected (1200-1850 nm) and finally diffuse reflectance from 1200-1850 nm.

Figure 3 below, shows the diffuse reflection technique.

Figure 3: Diffuse reflectance from a surface

Near IR spectroscopy can be used in many different fields where there is abundance of water in the material and there will not be a need for material preparation.

A spectrometer like Nirvascan can shine near-IR light from an IR lamp at 45 degree angle of incidence and detect the diffused reflectance at normal. The material to be detected could be pills, food grains, narcotics, plastic etc. Usually the material is grinded into fine powder and the Nirvascan spectrometer window is placed right over the powder and a measurement is taken.

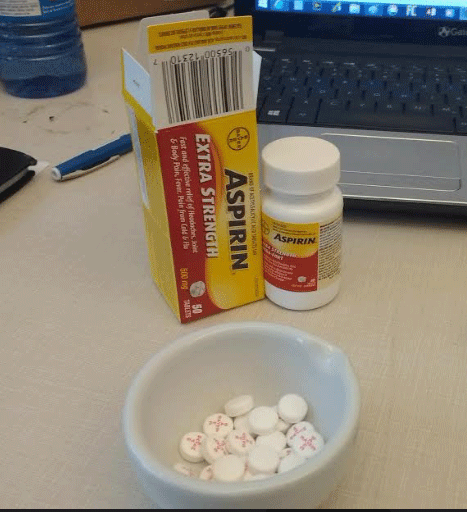

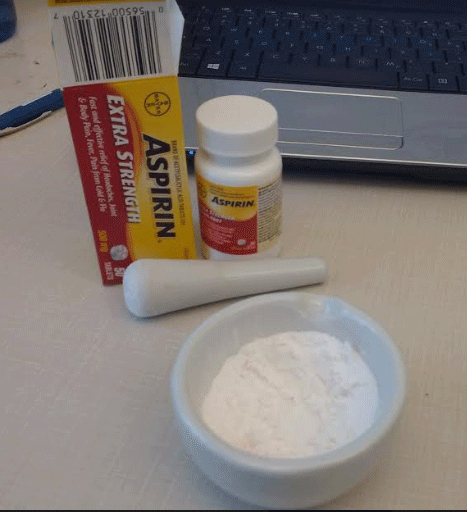

Figure 4 below shows the process of taking measurement for Aspirin.

Figure 4a -Aspirin in a mortar Fig. 4 b Ground Aspirin ready for measurement

Figure 4 c - Measuring Aspirin's near IR spectrum

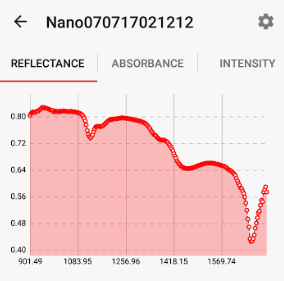

Figure 4 d - Reflectance spectrum of Aspirin shows absortion peaks

Two obvious absorption peaks are observed at nearly 1100-and 1600 nm which are associated with C-O stretching in Aspirin which has a large dipole moment. The larger the dipole moment of a bond, the stronger the near IR signal will be.

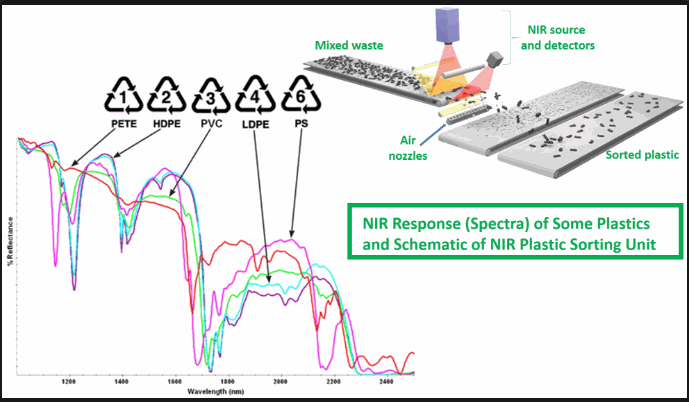

One interesting application of near IR is sorting plastic for recycling. Plastics are made using different types of polymers by using low temperature injection molding. Right now the process of sorting is done manually by using recycling codes. Different types of plastic on a moving rail are separated by workers by referring to their recycling codes as shown in figure 5.

Figure 5: Manually sorting plastic for recycling

Since each type of polymer has its own NIR spectral signature, the process of separation can be made much faster by identifying different types of plastic based on their spectral signature. Figure 6 below shows the concept where a NIR source and detector are used to collect the spectra of a mixed bunch of plastic. The detector also uses an imaging system to identify the position of different types of plastic based on their spectra on the moving belt. When the collection point arrives, programmed air nozzles puff air with different amounts of pushing force on different types of plastic which fall on different bins and get separated.

Figure 6: NIR sorting of plastics

The food industry can also benefit from the NIR technique because it can use near IR to quantify the fat, protein and moisture content. Wheat and Barley farmers need to know the protein and fat content of their harvested goods. Figure 7 shows the concept.

Other application examples are identification of narcotics, fungus detection, pill hardness quantification, mineral identification, food quality inspection, paint pigment testing, agricultural health monitoring, coating reflectance, etc. NIR techniques can also be used in identifying the physical characteristics of solid samples such as particle size and packing density of a material.

In summary, the NIR technique is a fast, non-destructive technique which requires no sample preparation and can be used in identifying, quantifying and sorting many materials in different industries. It can be used in process monitoring and is particularly useful to find the moisture content in different materials.

See the product details about the Nirvascan at http://www.nirvascan.com

References:

1- A review of near infrared spectroscopy and chemometrics in pharmaceutical technologies, Y.Reggo et al, Journal of Pharmaceutical and Biomedical analysis, (44), 2007.

2- Determination of Protein and moisture in wheat and Barley by near-infrared transmission, P. Williams et al. J. Agric. Food Chem, (33), 1985.

3- Development of method for non-destructive measurement of nitrate concentration in vegetable leaves by near-IR spectroscopy, Hiromitoichi Ito et.al, proceeding of the 18th world congress, the international federation of automatoic control, Milano , Italy, 2011.

4- Recycle and disposal of plastic food packaging waste 8, more about waste plastic sorting technologies, Robert Humphries, March 2017.