DESCRIPTION

Allied Scientific Pro (ASP) has developed and manufactured a laser cleaning system for aerospace market. Offering full control over a wide range of parameters allows for precise cleaning with the ability to retain patinas. With a long legacy of expertise in laser nano and micro machining process, ASP is capable of offering a state of the art laser system to address the needs of the aerospace and avionics. Our laser system is compact, robust and has a long lifetime with low or no maintenance for years. We are using the latest laser and scanner technology to offer high quality performance and speed efficient cleaning without causing damage to the object.

CONTACT US

Give us a call at 1-800-253-4107, or e-mail us and we will assist you immediately.

APPLICATIONS

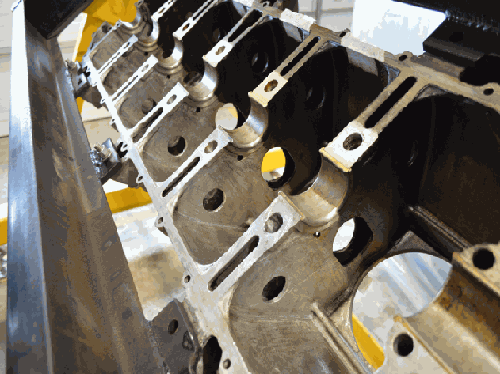

Paint Stripping and Cleaning the Brake Assembly

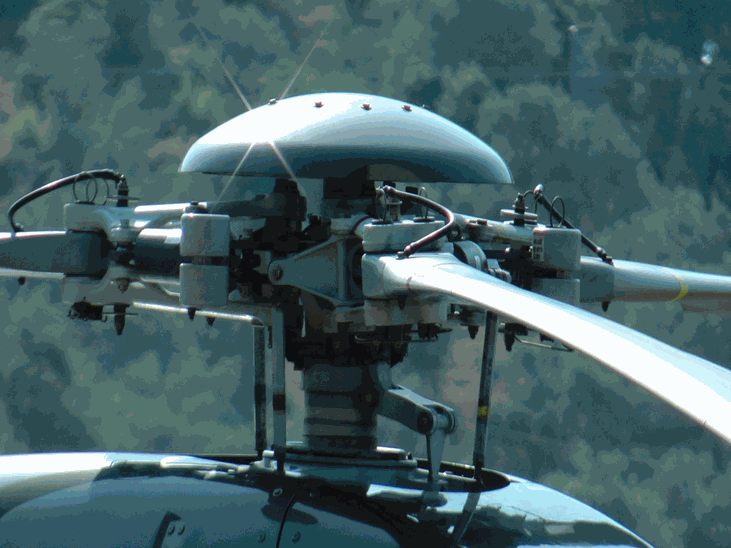

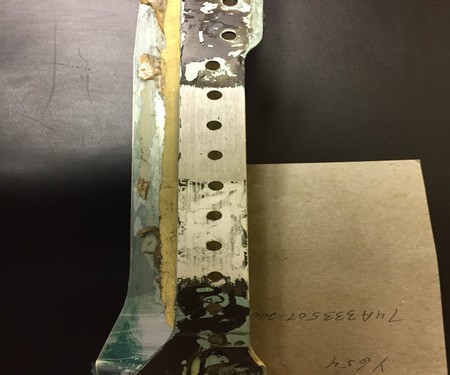

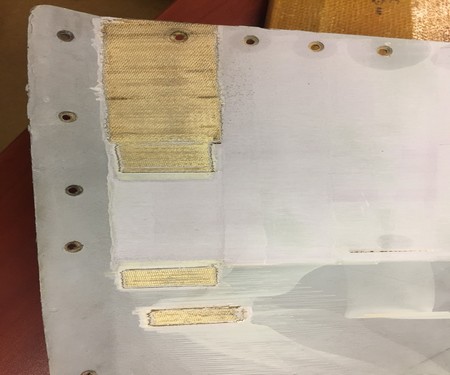

Helicopter Rotor Blade Cleaning

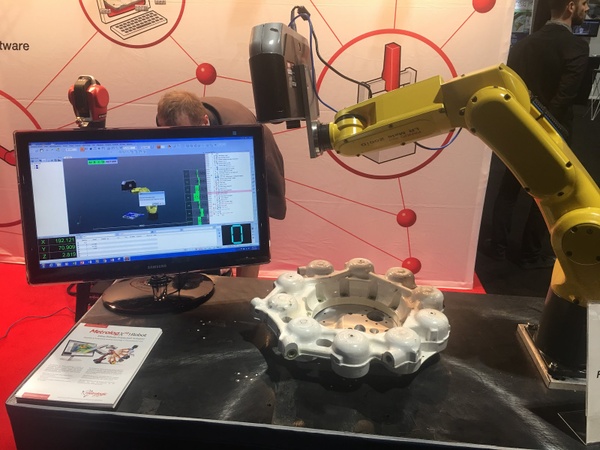

Paint Stripping and Avionic Refurbishing

Avionic Part Restoration

COST-SAVING

Minimal Preparation Time. No Disposal Cost. No Additional Gear Needed. Efficient.

Cleantech

Eco-Friendly. No Chemicals. No Blast Media. Consumes Only Electricity

user friendly

No Dangerous Projectiles. Computer Controlled. No Protective Wear Required. Low Noise Operation

SPECIFICATIONS

| Laser | Specification | Scanner Head | Specification | Laser Enclosure | Specification |

|

Laser Engine

|

100, 200, 500,1000 watts available

|

Flexible Configuration

|

Software allows for many types of scans; Round, Line, Square. Laser can be shaped to adapt to all types of surfaces |

IP Level

|

IP55

|

| Pulse Duration | 10 to 30 nanoseconds | Robust | Made of aluminum, 2 handle bars and protective lens cap |

Cooling

|

4 cooling fans fully protected from water |

| Cooling | Water-cooled | Working Distance | 12 to 12 inches | Handle Bar | Robust handle bars on each side for manual handling |

| Estimate Lifetime Expectancy |

10 years

|

|

|

Extension Electrical Cord | 30 feet/120V |

|

Repetition Rate |

1 to 55 KHz |

|

Computer |

Robust computer or tablet with full control for simple use | |

| Peak Power | Kilowatt | Software | EZClean software included | ||

| Design | No moving parts in the laser engine |

|

|

Laser Presets | 3 presets cleaning process included |

| Voltage & Power Consumption | 3x400-480VAC ± 10% 50/60Hz/ 4200Watts |

|

KEY ADVANTAGES OF USING THE LASER CLEANING INSTEAD OF ALTERNATIVE METHODS

| Cleaning Technique | Laser Cleaning | Dry Ice | Sand Blast | Glass Beads | Walnut Shells | Water Jet | Stream | Chemical Solvents |

| Waste for Disposal | No |

No

|

Yes

|

Yes

|

Yes

|

Yes

|

No |

Yes

|

| Abrasive |

No

|

No

|

Yes

|

Yes

|

Yes

|

No | No | No |

| Toxic Waste |

No

|

No

|

Yes

|

Yes

|

Yes

|

Yes

|

No |

Yes

|

| Electrically Conductive |

No

|

No

|

No | No | No |

Yes

|

Yes

|

Yes

|

| Consummables Needed |

No

|

Yes |

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

| Other Gear Required |

No

|

Yes |

Yes

|

Yes

|

Yes

|

No |

Yes

|

Yes

|

| Preparation Intensive |

No

|

No |

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

| Environment Friendly | Yes | CO2 No | No | No | No | No | No | No |

| Noise Level | Very Low | Very High |

Very High

|

Very High

|

High

|

High | Medium | Low |

| Vibration Level | No |

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

Medium | No |

| Dry Process | Yes |

Yes

|

Yes

|

Yes

|

Yes

|

No | No | No |

| Hazardous | Low | High | Very High | Very High | Very High | High | High | Medium |

| Causes Airbone Particles | No |

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

Yes

|

No |

| Works on Hot or Cold Surfaces | Yes | Sometimes |

Yes

|

Yes

|

Yes

|

No | Yes | No |

| Extra Nozzle or Tools to Shape Flow | No | Yes |

Yes

|

Yes

|

Yes

|

Yes | Yes | No |

| Performance Caomparison | Excellent | Great | Ok | Ok | Limited | Ok | Poor | Limited |