Imagine a world where cleaning surfaces, removing rust, and maintaining valuable artifacts are done with lightning speed, precision, and zero environmental impact. Welcome to the world of laser cleaning technology! In this blog post, we will delve into the fascinating realm of laser cleaning applications, its wide-ranging uses, and how it is revolutionizing industries across the globe.

Short Summary

Laser cleaning technology is a non-contact, environmentally friendly method with numerous applications.

It can be used for paint and rust removal, surface texturing, coating removal and more.

Laser cleaning offers businesses safe operation with minimal environmental impact while providing superior quality results.

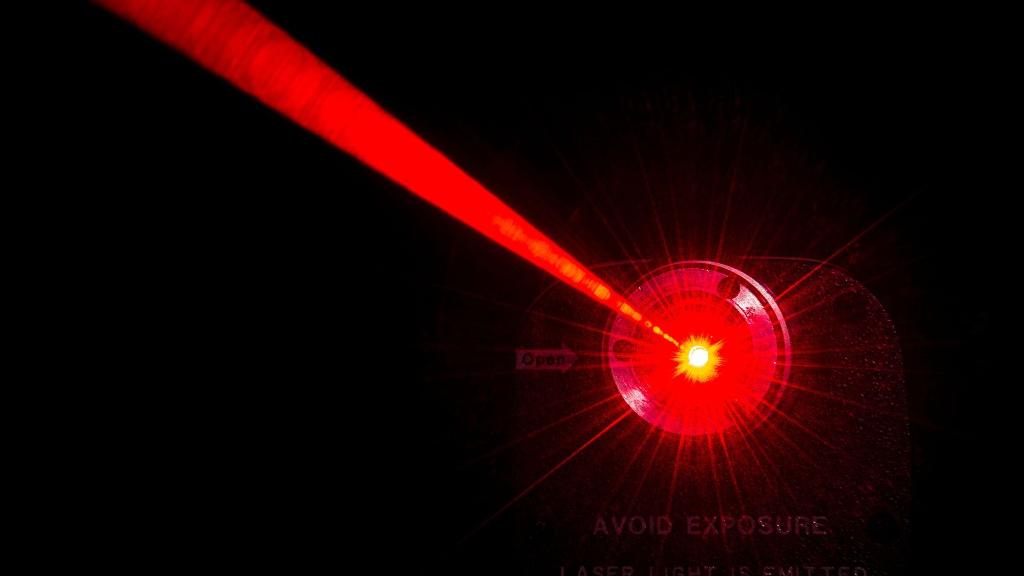

Understanding Laser Cleaning Technology

Laser cleaning is an innovative technology that uses high-powered laser pulses to efficiently and safely remove contaminants from a variety of surfaces. Unlike traditional cleaning methods, laser cleaning is non-contact, environmentally friendly, and highly versatile, making it the ideal solution for a range of applications, from automotive and aerospace industries to the restoration of precious artifacts.

Let's explore the many uses of this game-changing technology.

What are the applications of laser cleaning?

The potential applications of laser cleaning technology are almost limitless, as it can be tailored to a wide variety of tasks and industries.

In the following sections, we will delve into the details of specific applications, revealing the unique benefits and capabilities of laser cleaning in each context.

Paint Removal and Stripping

Traditional methods of paint removal, such as abrasive blasting or chemical processes, can be harsh on surfaces and the environment. Laser paint removal technology offers a much gentler and eco-friendly alternative. By using a high-powered laser beam, paint layers can be precisely removed from metal surfaces, such as steel, aluminum, and copper, without damaging the underlying substrate.

This makes it an ideal choice for industries that require accurate and efficient paint removal, like automotive or aerospace manufacturing.

Rust Removal

Rust removal can be a labor-intensive and time-consuming process using traditional methods. However, with laser cleaning technology, rust can be efficiently eliminated from metal surfaces without physical contact. Not only does this protect the integrity of the surface, but it's also environmentally friendly and cost-effective.

Applications for laser rust removal can be found in industries such as automotive, aerospace, and electronics, where maintaining the pristine condition of components is critical for performance and longevity.

Oxide Removal

Oxide layers and impurities can negatively impact the performance and appearance of metal surfaces. The precision and efficiency of laser cleaning technology make it an ideal solution for oxide removal. By directing a high-powered laser at the surface, the oxide layer is effectively broken down and removed without damaging the underlying material.

Laser oxide removal is perfect for industries that require clean, oxide-free surfaces, such as electronics or aerospace manufacturing.

Coating Removal

Removing coatings from surfaces can be a challenging task using traditional methods, as they often require harsh chemicals or abrasive materials. Laser cleaning technology, also known as laser ablation, offers a safer and more effective alternative. It uses a laser beam to selectively remove coatings from surfaces without affecting the base material.

This precision makes it a popular choice for industries such as automotive, aerospace, and medical equipment manufacturing, where maintaining the integrity of components is crucial.

Surface Texturing

Laser surface texturing is an innovative method for creating highly controlled surface textures and patterns on various materials. This process can enhance the tribological performance of surfaces, increasing wear resistance and improving surface adhesion.

Applications for laser surface texturing include automotive components, medical devices, industrial equipment, and consumer products, demonstrating the versatility and effectiveness of this laser cleaning application.

Surface Preparation

Surface preparation is a critical step in many manufacturing processes, and laser cleaning technology offers a fast and efficient solution. By using a laser to clean and prepare the surface of materials, contaminants such as lubricants, ferrous and non-ferrous metals, and other debris can be effectively removed. This ensures optimal adhesion and performance during subsequent processes, such as painting or welding.

Industries that benefit from laser surface preparation include automotive, aerospace, and medical equipment manufacturing.

Surface Cleaning

Laser surface cleaning provides a rapid, efficient, and environmentally friendly way to remove contaminants from various surfaces, including metals, marble, granite, limestone, concrete, and wood. As a non-contact process, it is highly effective in eliminating contaminants such as rust, mold, paint, oxide, and other residues.

Applications of laser surface cleaning span across industries like automotive, aerospace, medical, and industrial manufacturing, as well as restoration and preservation projects.

Mold Cleaning

Molds used in the production of food, plastic, rubber, composite, and glass products require regular cleaning to maintain their performance and longevity. Traditional cleaning methods can be harsh and potentially damaging to the mold surfaces.

Laser mold cleaning offers a gentle, residue-free solution that can clean even hot molds in situ, making it an ideal choice for industries that rely on molds for production.

Graffiti Removal

Removing graffiti from surfaces can be a challenging task using traditional methods, often requiring harsh chemicals or abrasive techniques that can damage the underlying surface.

Laser graffiti removal offers a fast, effective, and environmentally friendly alternative. By using a laser to heat the paint layer, it evaporates, leaving the surface unharmed. This technology is particularly useful for maintaining the appearance of buildings, monuments, and other structures without causing further damage.

Oil and grease removal

Removing oil and grease from surfaces can be difficult and time-consuming using traditional methods. Laser cleaning technology offers a faster and more efficient solution for oil and grease removal. By using a laser beam to heat the oil and grease on the surface, they vaporize and are effectively removed.

Laser cleaning is a cost-effective and environmentally friendly method for removing oil and grease from surfaces, making it ideal for industries that require clean, contaminant-free surfaces.

Adhesive bonding preparation for metals

For strong, long-lasting adhesive bonds between metals, the surfaces must be free of contaminants and oxides. Laser cleaning technology provides an efficient and accurate method for preparing metal surfaces for adhesive bonding. By removing contaminants and oxides from the surface, laser cleaning ensures optimal adhesion and performance in industries such as automotive and aerospace manufacturing.

Restoration and preservation

Laser cleaning technology offers a safe and effective method for restoring and preserving cultural heritage sites, monuments, statues, and valuable heirlooms. By removing dirt, grime, and other unwanted substances without damaging the substrate, laser cleaning is a valuable tool in the conservation of precious artifacts.

Its non-contact and environmentally friendly nature makes it particularly suitable for delicate surfaces and materials.

Industrial Equipment Cleaning

Maintaining the cleanliness of industrial equipment is essential for optimal performance and longevity. Laser cleaning technology offers a fast, efficient, and environmentally friendly solution for cleaning a wide range of equipment, from automotive components to aerospace parts.

Its non-contact, non-abrasive nature ensures minimal damage to surfaces while effectively removing contaminants.

Medical Equipment Cleaning

Proper cleaning and maintenance of medical equipment are crucial to ensure its functionality and safety. Laser cleaning technology provides an effective method for cleaning medical equipment, removing contaminants without causing damage to delicate components.

This non-contact, non-abrasive approach is particularly suitable for sensitive medical devices and equipment.

Preparation for Welding and Blazing

In welding and brazing processes, surface cleanliness is essential for strong, durable bonds. Laser cleaning technology offers an efficient method for preparing surfaces for welding and brazing, removing contaminants and providing a clean, oxide-free surface.

This results in improved weld quality, reduced welding time, and enhanced safety during the process.

Laser Cleaning for Marking

Permanent marking on surfaces often requires the removal of contaminants and coatings to ensure clear, long-lasting marks. Laser cleaning technology provides a precise and efficient method for preparing surfaces for laser marking. By removing contaminants and coatings without affecting the base material, laser cleaning ensures high-quality marks in industries such as automotive, aerospace, and medical equipment manufacturing.

Restoration of vintage or antique furniture

Vintage and antique furniture often require delicate cleaning and restoration to preserve their beauty and value. Laser cleaning technology offers a gentle, non-contact method for removing dirt, grime, and other unwanted substances from the surface of furniture without causing damage.

This makes it an ideal solution for restoring and preserving valuable antique furniture.

Removing contaminants

Laser cleaning technology provides a fast, efficient, and environmentally friendly method for removing contaminants from various surfaces, such as metals, marble, granite, limestone, concrete, and wood. Its non-contact, non-abrasive nature makes it an ideal choice for industries requiring clean, contaminant-free surfaces, such as automotive, aerospace, medical, and industrial manufacturing.

This technology is becoming increasingly popular due to its ability to quickly and effectively remove contaminants without damaging the underlying surface. It is also cost-effective, as it requires minimal labor and no additional chemicals or solvents. Additionally, laser cleaning is a safe and environmentally friendly process, as it is a safe and environmentally friendly process.

Removal of adhesive residues or labels from various surfaces

Removing adhesive residues or labels from surfaces can be challenging and time-consuming. Laser cleaning technology offers a fast, accurate, and environmentally friendly solution for removing adhesive residues or labels from various surfaces.

By using a laser beam to heat the adhesive or label, it can be effectively removed without causing damage to the underlying surface.

Anode assembly cleaning

Anode assembly cleaning is crucial for maintaining the performance and longevity of machines and devices. Laser cleaning technology provides a fast, efficient, and environmentally friendly solution for cleaning anode assemblies by removing impurities such as carbon residue and contaminants from casing and short rods.

It also prepares anode and cathode surfaces for welding, ensuring optimal performance and longevity.

Innovative Use Cases

Laser cleaning technology continues to find innovative use cases across various industries, such as mold cleaning, tool cleaning, and surface preparation. Its versatility, efficiency, and environmentally friendly nature make it a valuable asset in a wide range of applications, from automotive and aerospace industries to the restoration and preservation of precious artifacts.

What are the industries that utilize laser cleaning?

From automotive and aerospace manufacturing to medical equipment and military applications, laser cleaning technology is revolutionizing industries across the globe. Its versatility, efficiency, and environmentally friendly nature make it an invaluable tool for a wide range of applications, ensuring clean, contaminant-free surfaces that are essential for optimal performance and longevity.

What materials can be laser cleaned?

Laser cleaning technology is suitable for a wide range of materials, including metals such as aluminum, stainless steel, titanium, copper, brass, nickel, and carbide. It can also be used on non-metal surfaces such as marble, granite, limestone, concrete, ceramics, and wood.

Its versatility and adaptability make it an invaluable tool for industries and applications that require precise and efficient cleaning.

Implementing Laser Cleaning Systems in Your Business

Successfully implementing laser cleaning systems in your business involves several key steps, including assessing your needs, choosing the right equipment, and training and safety considerations.

In the following sections, we will explore each of these steps in detail, providing guidance on how to effectively integrate laser cleaning technology into your operations.

Assessing Your Needs

Before implementing laser cleaning systems in your business, it's crucial to assess your specific needs. Consider factors such as the type of surface that requires cleaning, the degree of contamination, the necessary precision of the cleaning process, and the size of the area to be cleaned.

By understanding your unique requirements, you can select the most suitable laser cleaning system and achieve optimal results.

Choosing the Right Equipment

Selecting the right laser cleaning equipment and systems is essential for achieving the desired results. Factors to consider include power level, delivery system, cost, and manufacturer qualification.

Researching the credentials of the manufacturer and understanding the capabilities of the equipment will ensure that the system you choose is of superior quality and meets your specific needs.

Training and Safety Considerations

Proper training and safety considerations are crucial when implementing laser cleaning systems in your business. Operators should be trained in the safe and effective use of the equipment, including the proper handling of the laser and adherence to safety protocols.

Protective clothing and equipment, such as safety glasses, gloves, and face shields, should be utilized to minimize potential risks associated with high-intensity laser beams.

Can laser cleaning destroy bacteria?

Laser cleaning's ability to destroy bacteria makes it a promising option for sanitizing surfaces in various industries. In addition to its numerous cleaning applications, laser technology can be employed to eradicate bacteria effectively, ensuring clean and safe surfaces in industries such as food processing, healthcare, and more.

Conclusion

Laser cleaning technology is truly transforming the way we clean surfaces across numerous industries. Its ability to provide safe, efficient, and cost-effective cleaning solutions with minimal environmental impact makes it an invaluable tool in today's world.

From automotive and aerospace manufacturing to the preservation of cultural artifacts, laser cleaning is paving the way for a cleaner, safer, and more efficient future.