LASER CLEANING MACHINES FOR INDUSTRIAL PURPOSES: NUCLEAR, REFINERIES AND POWER PLANTS

Nuclear:

Solid-state lasers with fiber optic beam delivery have been found to be extremely useful tools for material processing applications such as cleaning, ablation, cutting, welding and drilling in radioactive environment due to ease in tool handling, flexibility, non-contact nature, and longer tool life, and enormous time and cost saving. Laser material processing in nuclear fields is mainly concerned with the maintenance of nuclear power reactor parts by laser cleaning and welding, fabrication of new components, and nuclear power reactor decontamination and decommissioning. In addition, laser cleaning is also being increasingly used for remote diagnostics in nuclear operation. Laser cleaning systems are gaining traction in the maintenance of nuclear plants for the removal of impurities or contaminants deeply embedded within the surface of a material. Laser cleaning systems are used in the removal of radioactive concrete layers to avoid any possible contact with the radiation.

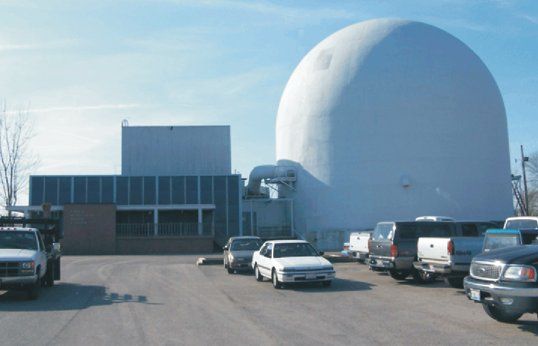

Decommissioned nuclear plant at Piqua, OH

Refineries and Power Plants:

Hydro turbine shaft

These lasers allow wear-free and selective cleansing of molds and tools from process residues such as carbon black, silicone, rubber, vulcanization residues or oils, and fat. Similarly, high-power short laser pulses remove oil and build-up by selective decoating. The original surfaces are neither damaged nor melted. Thus, laser cleaning systems allow a non-abrasive removal of oils, grease, and rust. This is usually necessary to prepare the surface for subsequent production steps such as the painting or welding. Laser cleaning systems provide a processing without any mechanical, chemical, or unauthorized thermal load on the carrier material.

Other Industries:

We know some other industries such as; printing to clean the anilox steel roller, molding cleaning insert mold after a certain number of cycle to maintain the quality of the mold, wind turbine repair and maintenance. Other application will be undercover in the next few years.

HAVE ANY QUESTION ?

One of our laser cleaning specialists will be glad to assist you further.