Summary of Radioactive Decontamination Case Study

Figure 1: Laser Decontamination Demonstration

Introduction

Allied Scientific Pro develops and manufactures laser cleaning, paint stripping and radioactive waste decontamination systems.

Committed to developing the laser technology as an effective, environmental, and user-friendly method for the Nuclear Industry, Allied Scientific Pro is working in collaboration with radioactive waste treatment facilities and nuclear plants.

Allied Scientific Pro visited a facility to demonstrate the performance of the LaserBlast-100-RAD system. The results and discussion of that visit is explained and elaborated in this report.

The majority of the work performed is nuclear decontamination, measurement and repackaging of the low-level waste. These processes are intended to provide an environmentally friendly way to reduce the amount of waste that must go for disposal through recycling and return to the industry. Traditionally, mechanical decontamination methods such as sandblasting, grinding, and polishing are used.

Basic Safety training on handling Laser technology was provided by Allied Scientific’s staff Then, training on the safe and effective way to use this technology, through video demonstration and basic hands-on, was also provided. The customer also provided basic safety training on Radiation control and exposure since the team will conduct the test in an area posted as a radioactive area.

All the contaminated pieces of equipment were positioned inside an enclosure controlled by negative pressure ventilation. All the observers could see the work performed inside the enclosure through a glass window, protecting them from any exposure or airborne contamination.

A customer technician and a Radiation Protection Technician (RCT) operated the Laser Unit inside the controlled area. Observers and the lead engineer were also located in the clean room. A two-way communication system was in place to help the Lead Engineer communicate with the technician and help him with the unit manipulation.

Results

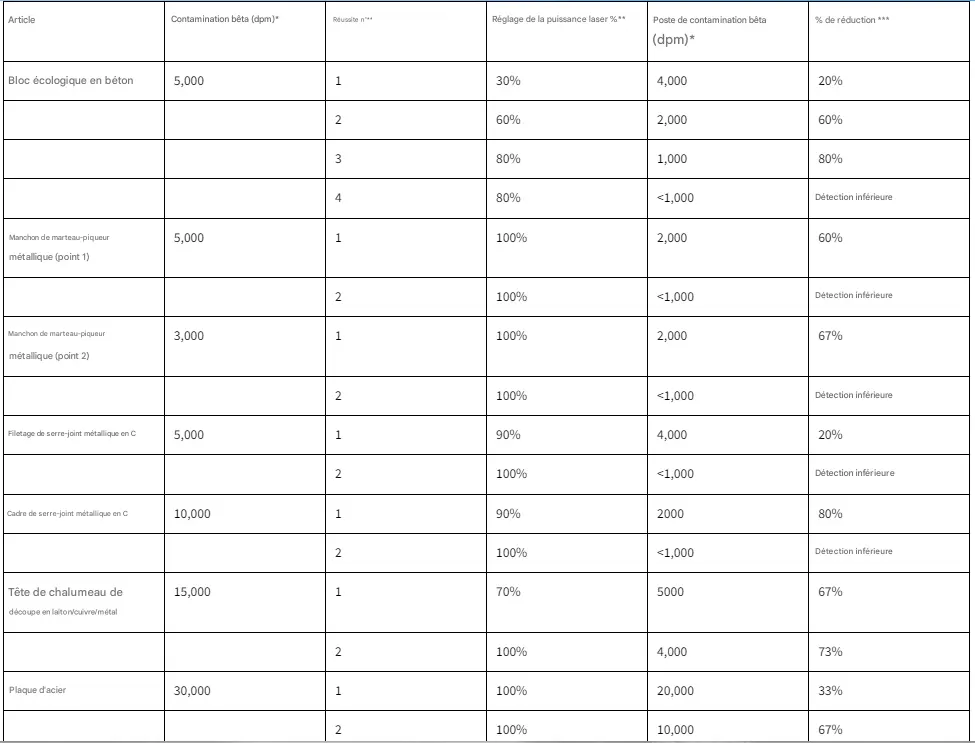

Using the 100W pulsed laser system, between 1-4 laser passes were done on concrete, metal tools, and steel plates. The results are shown in Table 1 below.

Table 1: Laser decontamination of various parts

*Contamination levels reported utilizing trained and qualified RCT utilizing handheld real time instrumentation, the Ludlum Model 12 Ratemeter. Post level analysis happened in real time inside the contamination area.

**Each pass of the laser was done at the instruction of the Allied Scientific Pro’s Mechanical Engineers recommendation. The Laser was adjusted depending upon the observed results to find the most efficient power and method for passing the laser over the contaminated area.

***The “below detect” notation above does not indicate the contamination is completely gone but rather that it is below the confidence level of the instrumentation used. In this case the instrumentation was a handheld real time instrumentation, the Ludlum Model 12 Ratemeter.

Discussion

A large percentage of the Beta contamination was removed by the 100W pulsed laser system as shown in Table 1. The far right column shows that increasing the number of laser passes will significantly increase the percentage of Beta contamination removed.

The concrete is of a porous composition. The laser simply removes a very small amount of the surface area, but the contamination is able to go deeper into the concrete. The general porosity of the concrete demanded multiple passes; however, after adjustments to the machine and several passes, the section of the previously contaminated concrete was found to be less than the detection limit and therefore met the release limit criteria.

The metal is not nearly as porous as the concrete, and the contamination tends to stay closer to the surface. In this case, the laser removing a very fine amount of surface area can be effective. For the jackhammer sleeves, the engineer moved the power to 100%, and after two passes, the material was less than the detection level and met the release limit.

The C-clamps were made of a more hardened steel, and since the tool could be reused for its intended purpose, decontamination without damage to the tool was important. The power was moved to 90% and was effective, but not complete. After adjusting to 100% power and making a second pass, the threads on the c-clamp were found to be below the detection levels and met the release limit.

The stainless steel tote lid was tested. Stainless steel tends to be more complicated or resistant than other metals to decontamination techniques. However, the materials tested were decontaminated successfully. It is important to note that the tested (suggestion: testing was done on the decontaminated portion (suggestion: area) of the lid, which was somewhat recessed and was also at a farther distance from the wand to the surface. However, this did not appear to cause an issue.

The steel plate had the highest level of contamination present, and as a result, it required three passes at full power. It also had 200 dpm alpha contamination, which was successfully removed.

The lead blanket could not be decontaminated with the laser unit because the fiber encasement of the lead itself is comprised of plastic and would only melt in contact with the laser, even at only 30% of the maximum power level.

Advantages

The advantages of the laser versus traditional decontamination tools include:

- Reduction of waste by-products such as sand, grit, and grinder wheels

- Safety for the operators with no moving parts

- Zero consumables

- Low cost of operations

- Fewer operators needed

- Quiet operation

- No damage to the articles being decontaminated

- More ergonomic use compared to mechanical tools

- Less force required to be applied to clean the sample as laser light beam produces zero physical forces on the operator

- Using the same laser cleaning settings and the same number of passes would create more consistent cleaning efficiency compared to mechanical tools which have less predictable settings

Conclusion

A larger, more powerful unit would probably be needed to fully assess the usefulness of this technology. The test did offer enough information to form some general observations.

To do a more effective and thorough testing, the following would be recommended:

- A 1000-watt unit to achieve approximated 5-10x cleaning rate compared to 100W.

- A nozzle with a roller system can be used to better control the angle and distance of the laser.

- A wider variety of contaminated materials. More concrete, wood, softer metals, etc.

- Higher and more varied levels of contamination.

- Measuring the timing of the passes to measure efficiency in time and, in turn, the labour costs

Normally, the laser would be accompanied by a vacuum system to remove the ablated materials. However, for this demo, the customer's vacuum system was used to avoid the radioactive contamination of Allied Scientific’s vacuum system. The contamination would have required the vacuum system to be disposed of as low-level radioactive waste, which was cost-prohibitive and unnecessary for this testing. This vacuum system would add an attribute (suggestion: would add a value)to the decontamination process concerning the safety of the operator and the contamination control.

In summary, the laser did prove to be an effective tool for the decontamination of radioactively contaminated parts, as tested. It is portable, quiet, creates very few by-products, and is a safer alternative to traditional mechanical decontamination methods. Using the laser method introduces many advantages compared to traditional mechanical methods.