Application du nettoyage laser avant le soudage laser des alliages d'aluminium

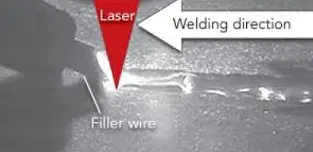

Aluminum alloys are typically used in the automotive and aviation industries due to their light weight, corrosion resistance, and flexibility. Aside from aluminum, which is the primary ingredient, other elements such as magnesium, manganese, silicon, tin, zinc, and copper can also be found in aluminum alloys. The parts for aluminum alloys are joined using several processes, including mechanical fastening, arc welding, and laser welding. In laser welding, disk lasers are typically used. Disk lasers are characterized by a thin active medium surrounded by a heat sink on one side and a laser output on the other. Filler wires used for typical welding operations are also used in the case of laser welding of aluminum alloys. Figure 1 shows the process of laser welding with filler wire.

Figure 1 : Soudage laser avec fil d'apport. Photo : Laser Focus World, Industrial Laser Solutions.

Although laser welding is a fast process compared to other similar techniques, a problem arises during it. A vast amount of porosity appears in the surface oxide layer of the alloy, which gives rise to a reduction in joint strength as compared to the parent material by a factor of 2 or more. Hydrogen atoms trapped on the surface as contaminants are released by heat and move into the surface. After the heat of laser welding is removed and the surface solidifies, it can lead to surface porosity. Figure 2 shows the porosity of the surface due trapping of hydrogen bubbles.

Figure 2 : Apparition de porosité due à des bulles d'hydrogène dans les alliages d'aluminium. Image tirée des produits de soudage et de coupage ESAB.

The molten aluminum pool created by the laser welding process traps hydrogen molecules, which are released as porosity when the material solidifies. Other organic surface contaminants, such as oil and grease, can also contribute to hydrogen molecule trapping. The hydrogen bubbles typically move more slowly than the speed of liquid solidification, and hence they get trapped. The bubble speed, which depends on several properties such as the bubble radius, fluid density, and viscosity, can be calculated. The diameter of the trapped hydrogen bubbles is typically of the order of tens of microns.

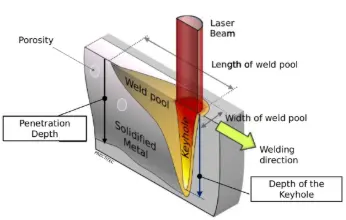

Outre le piégeage des molécules d'hydrogène dans la couche d'oxyde superficielle de l'alliage, lorsque la fluence laser (puissance surfacique) dépasse une certaine limite (de l'ordre du mégawatt par centimètre carré), lors d'un procédé appelé soudage en trou de serrure, la porosité peut pénétrer dans la masse du matériau. Lorsque le faisceau laser à haute densité énergétique évapore l'alliage d'aluminium, il génère une forte pression de recul et pénètre profondément dans le matériau. Si la tension superficielle du matériau est supérieure à la pression de recul de la vapeur ou si le matériau se solidifie rapidement, les bulles sont piégées dans la zone de chaleur et forment de grandes porosités de l'ordre de 0,5 micron de diamètre. La figure 3 illustre le soudage en trou de serrure et la porosité en trou de serrure.

Figure 3 : Soudure en trou de serrure et porosité en trou de serrure. Image tirée de Research Gate.

To fix this problem, laser cleaning of the aluminum alloy surface can be performed prior to laser welding. The laser cleaning mechanism would clean the surface and remove most contaminants, preventing them from contributing to the formation of porosity during laser welding. Based on a study of laser cleaning of an aluminum alloy that contained small concentrations of copper, fluorine, and manganese (Reference 1), it was found that, depending on the laser power, there can be a 10-90% porosity level produced. However, by performing laser cleaning prior to laser welding, the porosity level was reduced to less than 1% in all cases.

Figure 4 : Nettoyage par laser pulsé d'un alliage aluminium-silicone moulé. Image tirée de YouTube.

Allied Scientific Pro has offered a state-of-the-art laser cleaning system, LaserBlast-100, which uses a pulsed NIR laser and is highly effective at rapidly removing contamination from metal surfaces. The laser engine delivers 100W or more of power and a variable pulse width of 10-130 nsec, with a repetition rate up to 55 kHz. Figure 5 shows this laser cleaning system.

Figure 5:Système de nettoyage LaserBlast100 offert par Allied Scientific Pro.

Visit our dedicated website on Laser Cleaning Machines to learn more

Référence : Nettoyage laser avant soudage laser des alliages d'aluminium. Industrial Laser Solutions for Manufacturing, 2015.