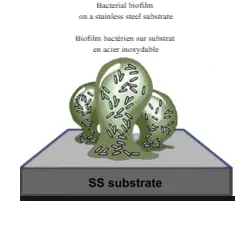

Traditionally, in the food industry, cleaning and disinfection are performed using detergents and water. Bacteria on surfaces form biofilms that adhere very strongly [Reference 1]. Studies have shown that these biofilms are difficult to remove with detergent solutions because they are sticky. Bacteria are easier to remove from liquid solutions than from the surfaces of solids such as stainless steel. Biofilms tend to resist removal by mechanical and chemical means. Other disinfection methods need to be explored to replace mechanical scribing and chemical methods. Figure 1 shows a stainless steel surface infected with bacteria.

Figure 1 : Surface en acier inoxydable infectée par des bactéries

Nettoyage au laser of surfaces infected with bacteria is a very effective method because the laser's thermal effects can disinfect the surface. Figure 2 shows Nettoyage au laser d'un plateau contaminé.

Figure 2 : Nettoyage au laser d'un plateau contaminé

Studies have been conducted to evaluate the effectiveness of different types of lasers for cleaning bacteria-contaminated surfaces. Pulsed lasers are usually used, but the choice of wavelength, pulse energy, and repetition rate is essential. In one study [Reference 2], seven different types of lasers, ranging from Ultraviolet (355 nm) to far IR (118 μm), were used to assess their effectiveness in killing Escherichia coli (E. coli) bacteria. Among the lasers, a CO2 pulsed laser at 10.6 μm and several Nd:YAG lasers operating at nominal, second-harmonic, and third-harmonic wavelengths were used.

The study showed that the CO2 pulsed laser was the most effective at removing bacteria, followed by the Nd:YAG laser at a specific energy density. The effect of UV on killing bacteria is well known, and the third most effective laser was the frequency-tripled Nd:YAG laser (355 nm emission). For testing purposes, E. coli was plated onto several plates, which were then irradiated with a laser. After this exposure, the plates were incubated for 24 hours at 37°. If laser sterilization worked, after growth, an area free of bacteria would be observed. Table 1 shows the different laser parameters and the observed area free of bacteria after exposure to these lasers.

| Laser | Longueur d'onde (μm) | Surface du faisceau (cm2) | Puissance moyenne (watts) | Temps d'exposition (sec) | Densité énergétique (J cm-2) | Surface de destruction bactérienne (cm2) |

| CO2 | 10.6 | 2.3 | 600 | 0.03 | 7.88 | 1.21 |

| Nd:YAG Lumonics | 1.06 | 1.65 | 200 | 16 | 1940 | 0.715 |

Nd: YAG Minilite 10 Triplé | 0.355 | 0.283 | 0.04 | 60 | 8.49 | 0.0365 |

Nd: YAG Mortel II-10 Triplé | 0.355 | 0.283 | 1 | 3 | 10.6 | 0.123 |

Tableau 1 : Comparaison des lasers pour la décontamination des surfaces infectées par des bactéries [Réf. 2]

Comme le montre le tableau ci-dessus, la densité énergétique du laser Nd:YAG Lumonics (impulsions de 10 ms avec une énergie de 10 joules à 20 Hz) était 246 fois supérieure à celle du laser CO2, et le temps d'exposition était également 533 fois plus long. Cette différence pourrait s'expliquer par le fait que l'eau absorbe le rayonnement infrarouge moyen (à 10,6 μm) beaucoup plus fortement que le proche infrarouge (1,06 μm). De plus, comme les bactéries E. coli vivent dans l'eau, elles sont plus facilement détruites.

Les longueurs d'onde UV à 355 nm ont également bien réagi à la stérilisation, comme le montre le tableau. Les lasers à fréquence triplée fonctionnaient à une fréquence de répétition de 10 Hz et avaient une durée d'impulsion d'environ 5 ns. En comparant le laser Surlite à fréquence triplée au laser Lumonics Nd:YAG, on constate qu'avec une puissance moyenne 200 fois inférieure et un temps d'exposition près de 5 fois plus court (densité énergétique presque 20 fois inférieure), le laser Surlite a atteint une surface de nettoyage du même ordre de grandeur que le laser Nd:YAG (0,123 cm² contre 0,715 cm²).

Aside from the effective lasers that killed the E. coli bacteria, others were ineffective. Some of these lasers included a far-IR laser at 118 μm, a diode laser at 0.81 μm, and an argon-ion laser at 0.488 μm. Several different energy densities were used for these lasers, but they proved ineffective at killing bacteria on the surfaces.

Allié Scientifique Pro has developed a fiber based laser cleaning system that has already been used and proved itself working in many different fields such as ruch removal in aviation industry, cleaning historical monuments and decontamination of a nuclear facility. These laser cleaning systems have a laser head, optics, and galvo mirrors that can make different-shaped beams. Typically, a linear beam is used, but to extend the application of these laser cleaning systems to surfaces infected with bacteria and to increase the beam's energy density, a circular spot size can be generated. As for the repetition rate and mean power, the specifications are compatible with the parameters of the Nd:YAG laser from Lumonics listed in Table 1.

La figure 4 présente le système de nettoyage laser d'Allied Scientific Pro. Il s'agit d'un système de 100 watts fonctionnant à une longueur d'onde de 1030 nm, appelé Laser Blast 100.

Figure 4 : Système Laser Blast 100 d'Allied Scientific Pro

Cleaning operations for contaminated metal surfaces in the food industry could greatly benefit from a laser cleaning system such as the one shown above. It is much faster and more effective than traditional mechanical and chemical methodmechanical and chemical methods.

Visit our dedicated website on Laser Cleaning Machines to learn more

Références :

- Élimination des bactéries adhérentes des surfaces par des faisceaux laser pulsés, A.K.Sadoudi, et. Al, Letters in applied microbiology 1997, 24, 177-179, 1996.

- Activités bactériennes comparatives de lasers fonctionnant à sept longueurs d'onde différentes, I.A. Watson et.al, Journal of biomedical optics 1(4), 466-472 (octobre 1996)