Railway Track Rust Removal Allied Scientific Pro Laser Cleaning Test Report

Report Overview

This document presents a detailed laboratory test report from Allied Scientific Pro, dated September 9, 2020, conducted at their Quebec facility, on behalf of a major railway engineering company. The report evaluates the performance of two laser cleaning systems—Laserblast 100 (100W) and Laserblast 200 (200W)—for the purpose of removing rust, mill scale, and dirt from rail ends to facilitate Flash Buttwelding. The objective was to achieve clean metal surfaces free of contaminants within a strict time constraint, ensuring optimal weld quality.

Purpose and Objectives

- Primary Goal: Remove rust, mill scale, and dirt from rail ends to guarantee contaminant-free metal surfaces.

- Welding Requirement: Clean surfaces are essential for high-quality flash buttwelding of rail sections.

- Time Constraint: Cleaning of two rail ends must be completed in 2 minutes or less to meet operational efficiency.

Equipment and Safety Measures

Equipment | Description |

|---|---|

Laserblast 100 | 100-watt laser cleaning system |

Laserblast 200 | 200-watt laser cleaning system |

Fume Extractor | Air filtration for safety |

Personal Protective Equipment | Laser glasses, steel-toed shoes, breathing masks, safety vests |

- Safety briefing was conducted prior to testing.

- Protective equipment ensured operator safety during laser ablation trials.

Testing Procedures and Parameters

Multiple trials were conducted using different laser settings to optimize cleaning performance.

Parameters adjusted included:

- Power (W)

- Pulse width (nanoseconds, nS)

- Frequency (kHz)

- Scan speed (mm/sec)

- Beam width (mm)

- Cleaning time (seconds)

Both 100W and 200W systems were tested across a range of settings to identify optimal cleaning conditions.

Visual and tactile inspections were performed post-cleaning to assess surface quality and temperature effects.

Detailed Trial Summary

Test No. | Power (W) | Pulse Width (nS) | Frequency (kHz) | Scan Speed (mm/sec) | Beam Width (mm) | Time (sec) | Notes |

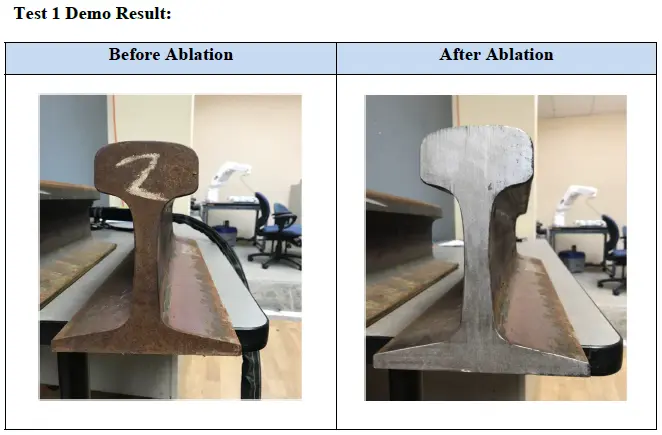

1 | 100 | 200 | 80 | 85 | 30 | 50 | Initial trial |

Test No. | Power (W) | Pulse Width (nS) | Frequency (kHz) | Scan Speed (mm/sec) | Beam Width (mm) | Time (sec) | Notes |

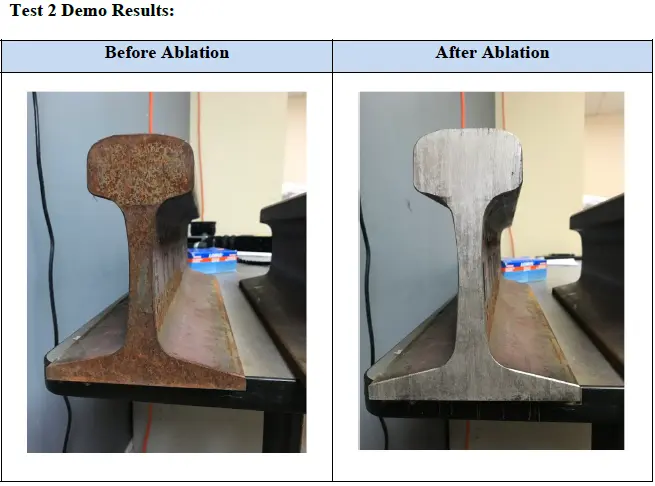

2 | 100 | 200 | 80 | 85 | 40 | 43 |

Test No. | Power (W) | Pulse Width (nS) | Frequency (kHz) | Scan Speed (mm/sec) | Beam Width (mm) | Time (sec) | Notes |

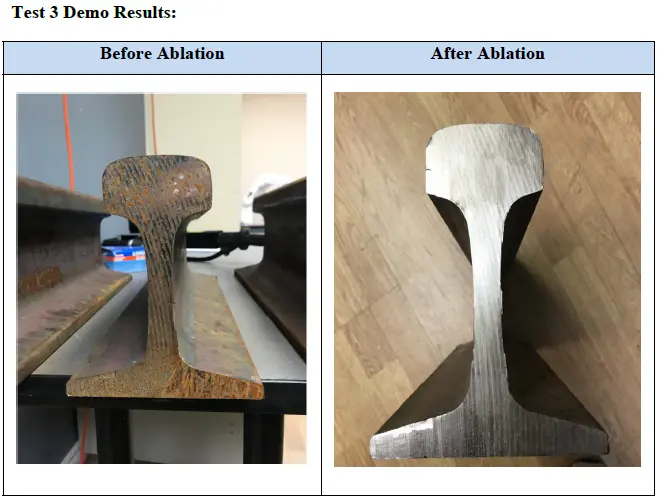

3 | 100 | 200 | 120 | 88 | 50 | 48 |

Test No. | Power (W) | Pulse Width (nS) | Frequency (kHz) | Scan Speed (mm/sec) | Beam Width (mm) | Time (sec) | Notes |

4 | 100 | 200 | 120 | 88 | 50 | 30 | Fastest for 100W |

Test No. | Power (W) | Pulse Width (nS) | Frequency (kHz) | Scan Speed (mm/sec) | Beam Width (mm) | Time (sec) | Notes |

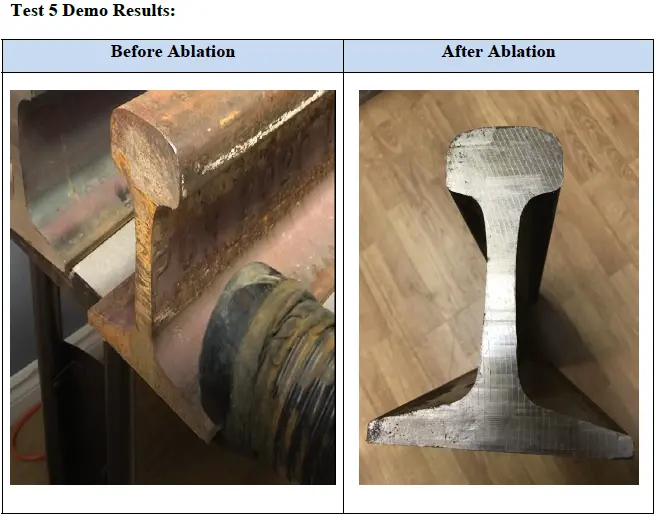

5 | 100 | 200 | 120 | 88 | 50 | 61 | Outlier due to non-laser issues |

Test No. | Power (W) | Pulse Width (nS) | Frequency (kHz) | Scan Speed (mm/sec) | Beam Width (mm) | Time (sec) | Notes |

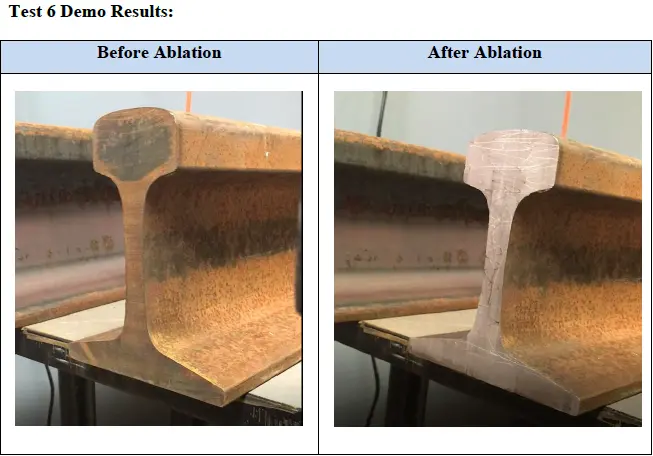

6 | 200 | 100 | 43 | 94 | 50 | 31 |

Test No. | Power (W) | Pulse Width (nS) | Frequency (kHz) | Scan Speed (mm/sec) | Beam Width (mm) | Time (sec) | Notes |

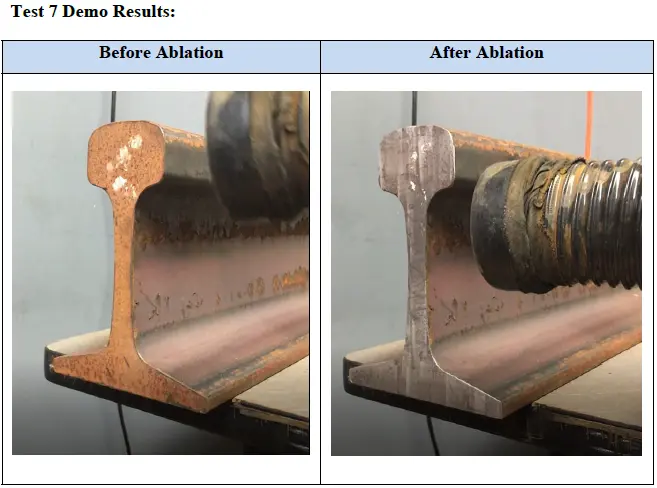

7 | 200 | 100 | 43 | 94 | 50 | 35 |

Test No. | Power (W) | Pulse Width (nS) | Frequency (kHz) | Scan Speed (mm/sec) | Beam Width (mm) | Time (sec) | Notes |

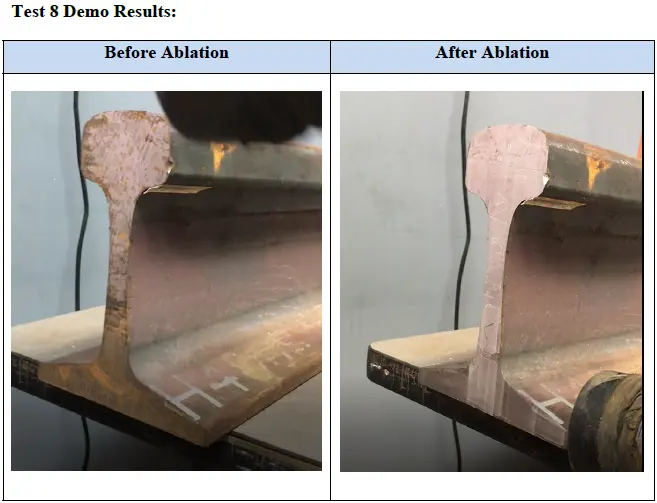

8 | 200 | 100 | 29 | 94 | 50 | 38 |

Test No. | Power (W) | Pulse Width (nS) | Frequency (kHz) | Scan Speed (mm/sec) | Beam Width (mm) | Time (sec) | Notes |

9 | 200 | 100 | 29 | 94 | 50 | 30 | Fastest for 200W |

Key Observations and Insights

Surface Quality:

Post-ablation, cleaned surfaces were visually comparable between the 100W and 200W lasers, showing effective removal of contaminants while maintaining surface integrity.

Thermal Effects:

Surfaces were tested by touch for temperature and found to be only tepid, indicating minimal thermal damage or overheating during cleaning.

Cleaning Time:

- 100W laser cleaning times ranged mostly between 30 to 50 seconds per rail side-cut, with one outlier at 61 seconds due to unrelated issues.

- 200W laser cleaning times ranged from 30 to 38 seconds, demonstrating slightly faster performance.

Power and Performance:

The 200W laser, despite similar cleaning quality, exhibited faster ablation and cleaning speeds due to higher power output, implying stronger energy interaction with the metal surface.

Operational Efficiency:

Both laser systems consistently met the requirement of cleaning two rail ends within two minutes, validating their suitability for the intended industrial application.

Conclusions

- Effectiveness: Both 100W and 200W Laserblast models are capable of efficiently cleaning rail ends to a standard acceptable for flash buttwelding within the required time frame.

- Performance Similarity: Visual and timing results do not reveal significant differences in cleaning quality; however, the 200W model offers operational advantages.

- Thermal Safety: No excessive heat buildup was detected, ensuring the process is safe for the metal and operators.

- Time Compliance: The critical operational time limit of 2 minutes for cleaning two rails was achieved by both systems, even with manual operation.

Recommendations

- Preferred Equipment: The report recommends selecting the 200W Laserblast system over the 100W model despite similar immediate performance.

- The 200W system offers greater power flexibility, allowing operators to optimize settings and possibly improve cleaning speed and quality over time.

- Higher output power widens the scope of potential applications beyond rail cleaning.

- With operator experience or robotic assistance, cleaning time per rail side-cut could be further reduced to below 30 seconds.

- Operator Training: Experience and precision in laser operation significantly influence cleaning speed and effectiveness.

- Future Potential: The 200W model’s broader power range enables innovation in cleaning parameters that can enhance overall process efficiency and quality.

Summary Table of Advantages

Feature | Laserblast 100 (100W) | Laserblast 200 (200W) |

|---|---|---|

Power Output | 100 watts | 200 watts |

Cleaning Time per Rail Side | 30-50 seconds (61s outlier) | 30-38 seconds |

Surface Quality | High, minimal thermal effect | Smooth when gentle setting used (low pulse width) |

Power Flexibility | Limited | Wide range, adjustable |

Operational Scope | Restricted | Versatile for multiple uses |

Recommended for Customer | Not preferred | Recommended |

Final Remarks

This laboratory test report by Allied Scientific Pro provides robust evidence that laser cleaning technology, specifically the Laserblast 100 and 200 systems, can efficiently prepare rail ends for welding by removing contaminants quickly and safely. The 200W Laserblast system is recommended for Engineering Facilities due to its greater power flexibility, potential for faster cleaning times, and broader application capabilities.

—-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------