LASER CLEANING FOR THE AUTOMOTIVE INDUSTRY

The laser surface preparation of metallic surfaces in the automotive industry is a unique method to support adhesive bonding that cleans with unmatched quality, repeatability,and reliability to ensure long-term adhesion performance and excellent electrical connectivity. Laser cleaning is gaining traction as it offers an environmentally friendly, precise, and profitable means of surface cleaning for bonding. In the automotive industry, several new grades of press-hardened steels (PHS) have been developed for the body-in-white (BIW) structure that combines desirable properties of strength and formability. Prior to assembling PHS components, the aluminum silicon coating must be removed to allow better weld surface capabilities. High-powered pulsed lasers are used to successfully remove the coating without affecting the mechanical properties produced by the weld bond. Laser cleaning systems are replacing the traditional brazing methods while increasing the process speed, minimizing heat effects on the assembly and reducing dependence on manual part cleaning.

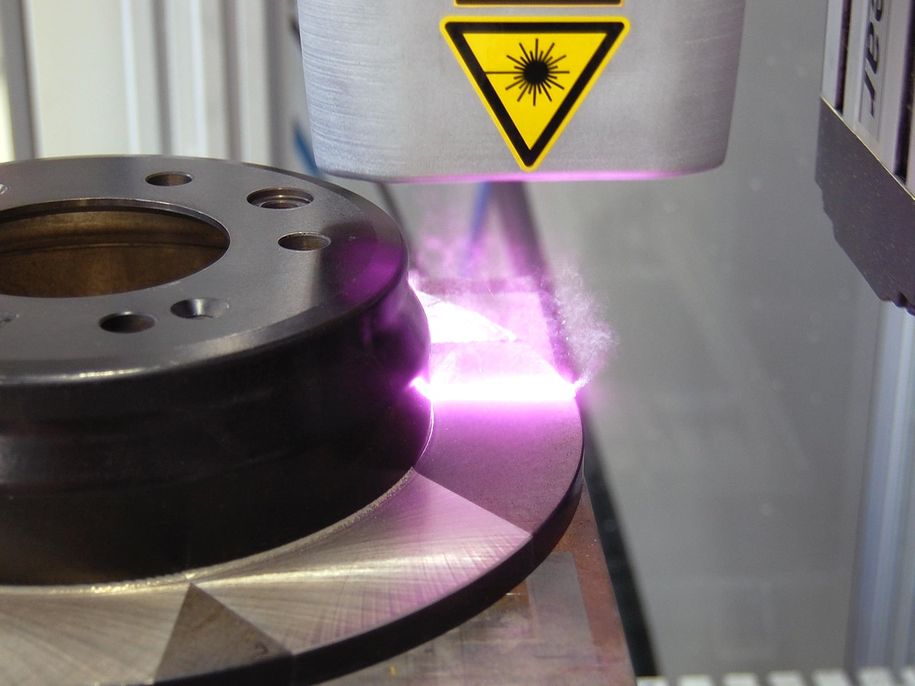

Brake disk laser cleaning

Laser cleaning systems are also used in other automotive applications such as decoating of disk brakes. With the huge demand from the automotive sector, implementations of laser cleaning systems on the production line are likely to increase.

Source : Laser Cleaning Market - Global Forecast to 2023, Markets and Markets, December 2017

HAVE ANY QUESTION ?

One of our laser cleaning specialists will be glad to assist you further