Nuclear Decontamination by Laser for Decommissioning

Nuclear energy is an important substitute for replacement of fossil fuels such as coal which contributes heavily to global warming. In the Canadian province of Ontario, where the production of electricity by coal burning power plants has been banned in the last few years, 59% of electricity is produced by nuclear power plants as compared to 23% hydroelectric, 11% natural gas and about 5% of clean energy (Solar wind). Therefore nuclear power plants play an important role in production of electricity. However, nuclear power plants do not last forever and need to be decommissioned after 30 to 40 years of operation. This is because parts get worn out and it would be unsafe to run the facility any further. Another reason is the possibility of the walls developing cracks.

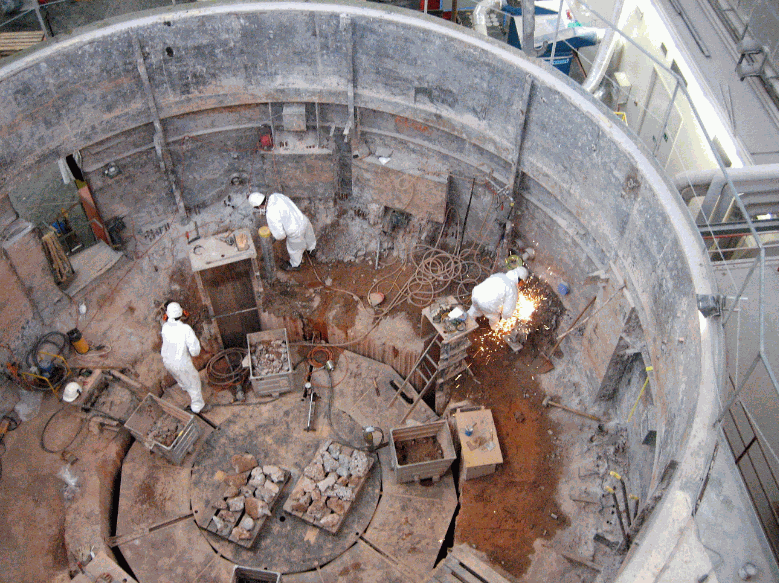

During nuclear decommissioning, normally a reactor is dismantled completely and all the parts are taken to a temporary repository which will then be transferred to a permanent geological repository. Some of the parts that are to be disposed of consist of valuable metals and alloys and it would be beneficial to decontaminate them so they can be reused rather than ending up as waste. There are many precious metals such as stainless steel available in the structure of nuclear power plants and it would be economical to recycle this material after decommissioning them. Usually in the decontamination process, there are layers of oxides which contaminate the walls of a nuclear power plant that need to be removed. Figure 1, shows a picture of one of these walls:

Figure 1: The oxide layer is visible on the interior wall of the nuclear power plant. This image is taken from the site belonging to the Swiss Federal nuclear safety inspectorate ENSI.

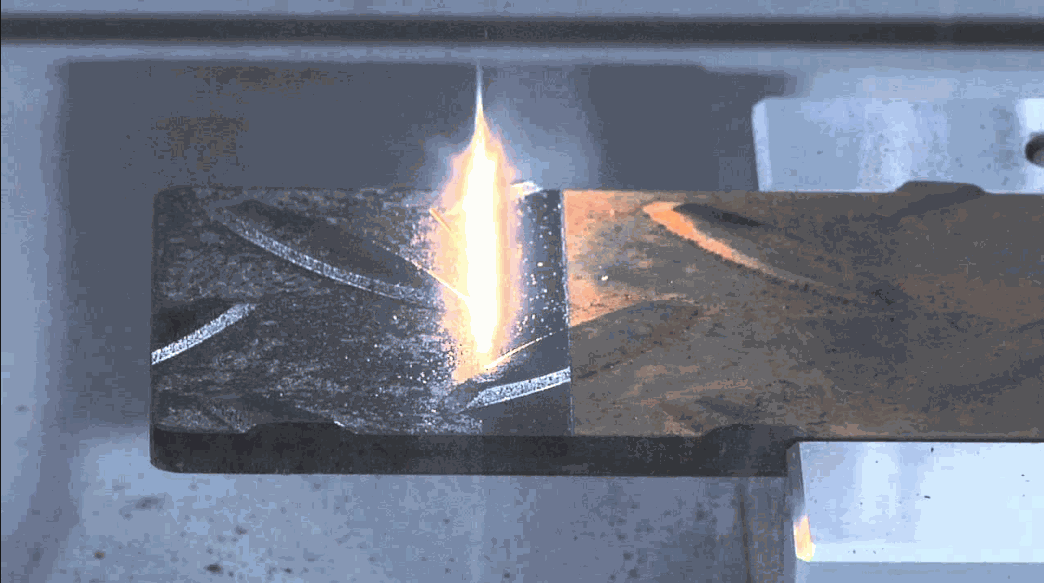

experimental studies, PhD thesis by Anton Leontyev.

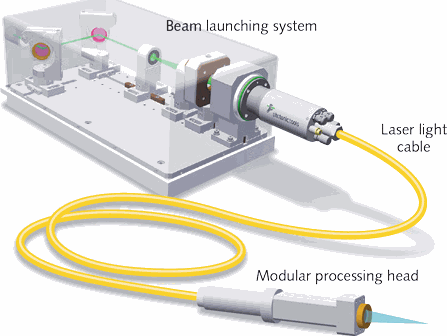

and Colin Walters, TWI website.

Inspectorate ENSI website.