Laser Oxide Removal - Technology and Systems

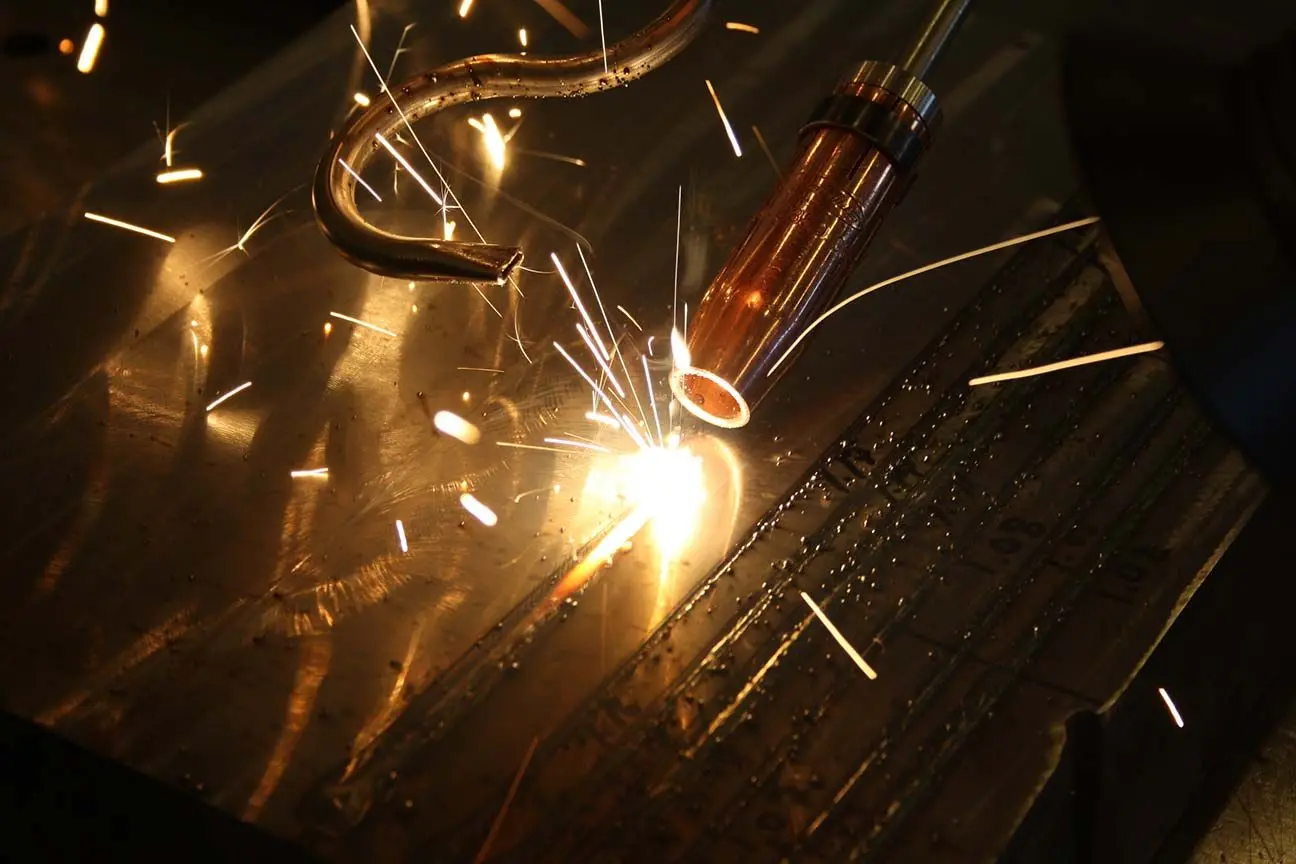

If you're in the business of welding, you know that dirty metal surfaces can be a big problem. Oxides and other contaminants can interfere with chemicals, paint adhesion and even weaken welds. That's where laser oxide removal comes in. Our cutting-edge laser's micron precision removes unwanted surface contaminants with accuracy.

Allied Scientific Pro Laser Oxide Removal Solution

You can target and completely remove black oxides in controlled layers and from specific areas. You don't have to worry about introducing impurities into your base metal or sheet metal parts. It's the perfect solution to improve welding results and eliminate common surface contamination issues before several surface treatments, such as powder coating or painting.

Unlike chemical treatments or mechanical brushes, which can damage delicate surfaces and pose a health hazard, fiber laser cleaning systems offer a safer, more effective way to continuously remove oxides from ferrous and non-ferrous metals alike. So, why settle for traditional oxide scale removal methods when you can do the job faster and more effectively with ASP's laser oxide removal machines?

Our Models - LaserBlast Product Lineup

Laserblast 100W

- 100 Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 200W

- 200Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 300W

- 300Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 500W

- 500Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 2000W

- 2000Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 1000W

- 1000Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Aluminum Oxide Removal

Aluminum combines strength and lightness. But have you ever noticed a gray oxide layer forms on its surface over time? That's an unavoidable consequence of exposure to oxygen and humidity. By using laser technology, you can eliminate aluminum oxide easily, leaving a clean and even surface ready for any coating process. This is especially important if you plan on welding the aluminum, as removing the oxide beforehand will ensure that your welds are as strong as possible. With ASP laser cleaning machines, aluminum oxide removal is a breeze.

Stainless Steel Oxide Removal

Stainless steel offers unbeatable corrosion resistance and aesthetic appeal. Unfortunately, welding or laser cutting often leaves behind unsightly blackening around the joints, preventing complete passivation and affecting the adhesion of any subsequent powder coating applied. But ASP fiber lasers provide a solution for completely removing black oxides. Our laser oxide removal tools clean and restore the shiny surface finish of stainless steel parts.

Convenience

COST-SAVING

- Minimal preparation time

- No disposal cost

- No additional gear needed

- Time-saving

USER FRIENDLY

- No dangerous projectiles

- Computer-controlled

- No protective wear required

- Low noise operation

CLEANTECH

- Eco friendly

- No chemicals

- No blast media

- Consumes only electricity

AI-DRIVEN

- Fully digital controlled

- Intelligent setting

- Setting on the fly

- Robotization available

Why Use Laser Technology For Oxide Removal

High-Performance Cleaning Solutions

Achieve an automated and repeatable process without the need for consumables! Remove oxide layers without abrasives that may harm your equipment or hazardous chemicals that require strict safety regulations.

Eliminate Guesswork and Maximize Efficiency

Our certified experts provide end-to-end services that ensure your system runs at peak performance - from installation to ongoing maintenance.

Maximum Uptime with Industrial-Grade Components

Our superior cleaning systems provide years of reliable, long-term performance with minimum maintenance.

Optimal Operations

Take advantage of our advanced technology to reduce downtime and increase efficiency without sacrificing safety or quality.

Click Here to Lease our Laserblast Cleaning System

Laser-Cleaning Systems

LASER AERO

This high-powered laser cleaning system is ideal for surface cleaning and paint removal applications in the aerospace and automotive industry. Save time with laser rust removal, paint stripping, and mold cleaning for preparing surfaces for painting. It's also more environmentally friendly than traditional abrasive cleaning technology.

- Scanner Head: Software allows for many types of scans: round, linear, and square. The laser beam can adapt to various surface shapes.

- Estimated Lifetime Expectancy: 10 years

- Computer: Robust, easy-to-use computer or tablet gives full control over cleaning

- Software: EZClean software included

- 3 presets cleaning process included

LASER BLAST

A handheld laser cleaning solution ideal for grease cleaning, coating removal, nuclear decontamination, and pre-treatment or preparing surfaces for welding. A great alternative to traditional surface preparation techniques.

- Power: 100Watts

- Beam Size: 10 - 100 mm

- Estimated Life Expectancy: 60K hours

- Fume Extraction System: vacuum

- Manual Control: handheld

LASER ART

An ideal laser surface cleaner for building restoration projects; compatible with stone, metals, wood, and many other materials. Gentle enough for art, sculpture, and classic car restoration projects. Also, laser paint removal, such as removing graffiti, is a time-saving and efficient alternative to sandblasting or other abrasive cleaning methods.

- Scanner Head: Software allows for various scans: round, linear, or square. The laser light beam can be adapted to different shapes of surfaces.

- Estimate Lifetime Expectancy: 10 years

- Computer: Robust and easy-to-use computer or tablet gives full control over the laser cleaning process

- Software: EZClean software included

- 3 preset laser cleaning processes included

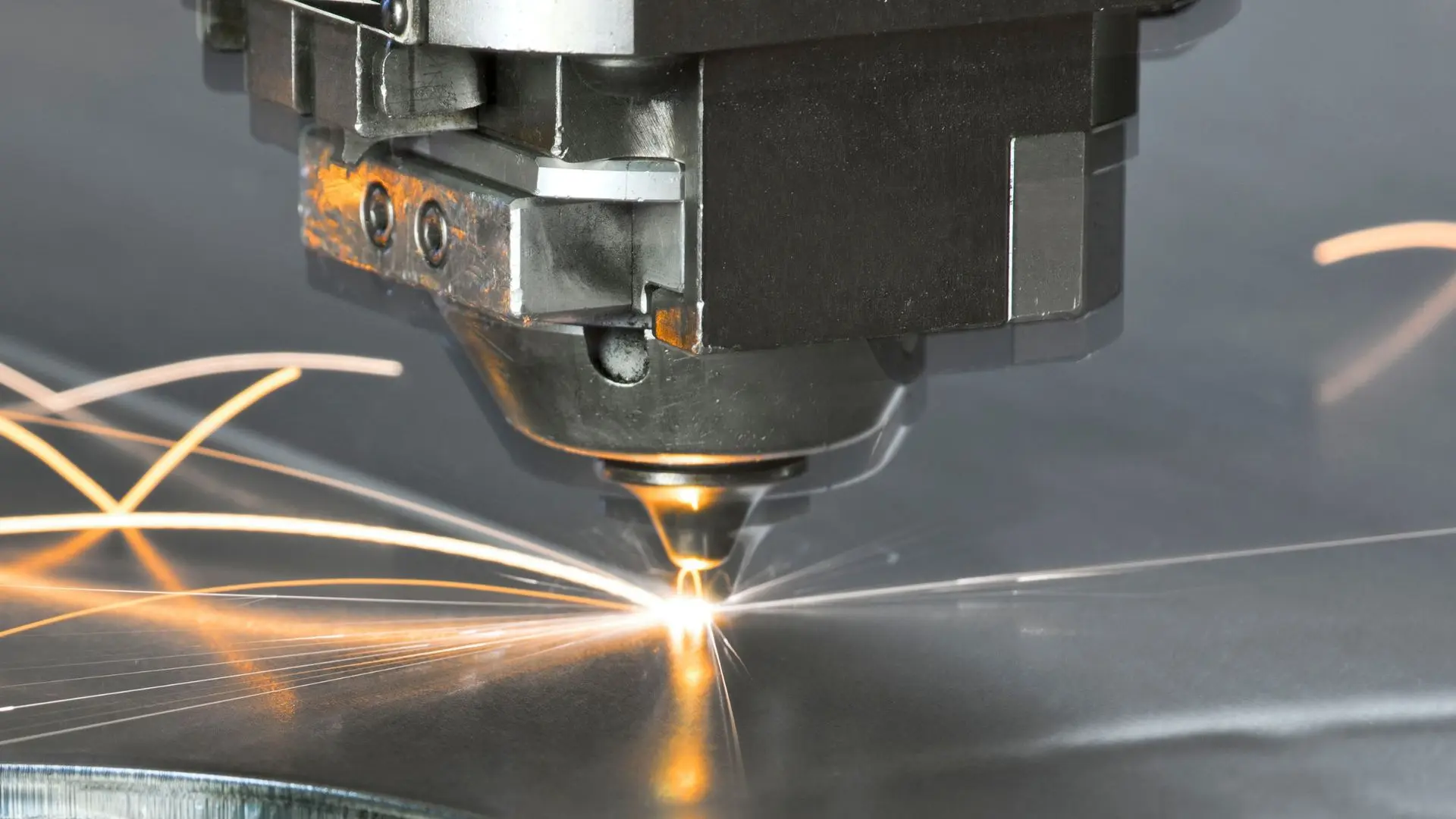

How Does Laser Oxide Removal Work?

Laser oxide removal is a process that uses high-powered lasers to ablate the surface of metals, removing oxidation and other impurities.

The laser creates heat, which causes rapid vaporization of the topmost layers - making them easier to remove. Laser energy can be adjusted to optimize performance and safety based on the material being cleaned.

After the affected area is exposed, it can be treated with various chemical compounds or processes to eliminate any remaining impurities. Laser oxide removal efficiently removes surface contaminants while helping protect the integrity of the underlying material.

Removing oxidation layers promotes better adhesion, mechanical properties, and longevity in the end product. Additionally, laser oxide removal can provide improved surface finish characteristics and fewer defects in manufactured components.

Applications of Laser Oxide Removal Automated Solutions

Laser oxide removal is used in a variety of manufacturing processes and applications.

- Automotive Industry: cleaning and preparing surfaces for painting or sealing; stripping old paint and coatings.

- Aerospace industry: preparing parts before welding or coating.

- Medical Device Industry: cleaning and polishing surgical instruments; removing paint and coatings from implantable hardware.

- Precision Optics Manufacturing: cleaning lenses and other optical components.

- Electronics Industry: micro structuring in microelectronic components.

Why Choose ASP Industrial Laser Cleaning Systems?

Features

- ASP's LaserBlast Cleaning systems offer a wide range of power options, including 100W, 200W, 300W, 500W, 1000W, and 2000W, allowing users to select the most suitable system for their needs

- Each system utilizes advanced photonics, mechanics, electronics, robotics, imaging, spectroscopy, and AI technologies in its design, and is highly effective at surface treatment and cleaning without using any chemicals or blast media.

- The digitally controlled system features an intuitive user interface that enables users to start cleaning instantly.

Benefits

- Cost-saving - With no additional chemicals or blast media required, ASP's Laser process helps reduce costs associated with traditional cleaning methods.

- Eco-friendly - No chemical pollutants are released during the laser cleaning process, making it one of the most environmentally friendly solutions available today.

- User-friendly – The interface and controls make it easy to operate and achieve faster cleaning than with traditional methods.

Experienced Technical Team

Our experienced technical experts are ready to take on your cleaning challenges. Our multi-disciplinary staff specializes in engineering solutions incorporating photonics, spectroscopy, mechanics, electronics, robotics, AI, and computer programming.

Our expertise enables us to develop innovative laser cleaning machines and provide a cost-effective, user-friendly solution for all your cleaning needs.

So why wait? Get the job done right with ASP's LaserBlast Cleaning System.

Learn More About Laser Cleaning

Explore our latest articles and guides on laser cleaning technology, applications, and industry use cases.

How to Choose a Laser Cleaning Machine

Understand the key factors—laser power, material, and precision—to select the right system for your needs.

Laser Cleaning Applications: All Uses & Industries

Explore how laser cleaning is used in automotive, aerospace, cultural heritage, and manufacturing.

Environmental Evaluation of Abrasive Blasting

Compare traditional abrasive blasting with modern, eco-friendly laser cleaning methods.

Lead and zinc-based paint stripping using laser technology

Efficacy and cost benefits of laser technology in paint stripping compared to traditional methods.

Laser Cleaning Advantages: All 20 Benefits

From precission and efficiency to eco-friendliness and versatility compared to other methods.

Laser removal of epoxy coatings on stainless steel using beam scanning patterns as control parameters

How controlling the shape of marking patterns can achieve more uniform coating removal.

Nuclear Decontamination by Laser for Decommissioning

Advantages and challenges of laser cleaning technology in nuclear decontamination

Application of Laser Cleaning Prior to Laser Welding of Aluminum Alloys

Reduction of porosity levels in aluminum alloy laser welding by laser cleaning before welding.

Laser Cleaning Materials: Ultimate Guide on All Supported Ones

A complete list of materials and the suitable types of laser cleaning applications for them

SOME OF OUR VALUED CLIENTS & PARTNERS

we work in close partnership with our clients to ensure that all design needs are met in a timely manner. Our specialists and engineers work closely together to develop tailor-made solutions that meet the industry evolving needs.