Laser Paint Removal - Technology and Systems

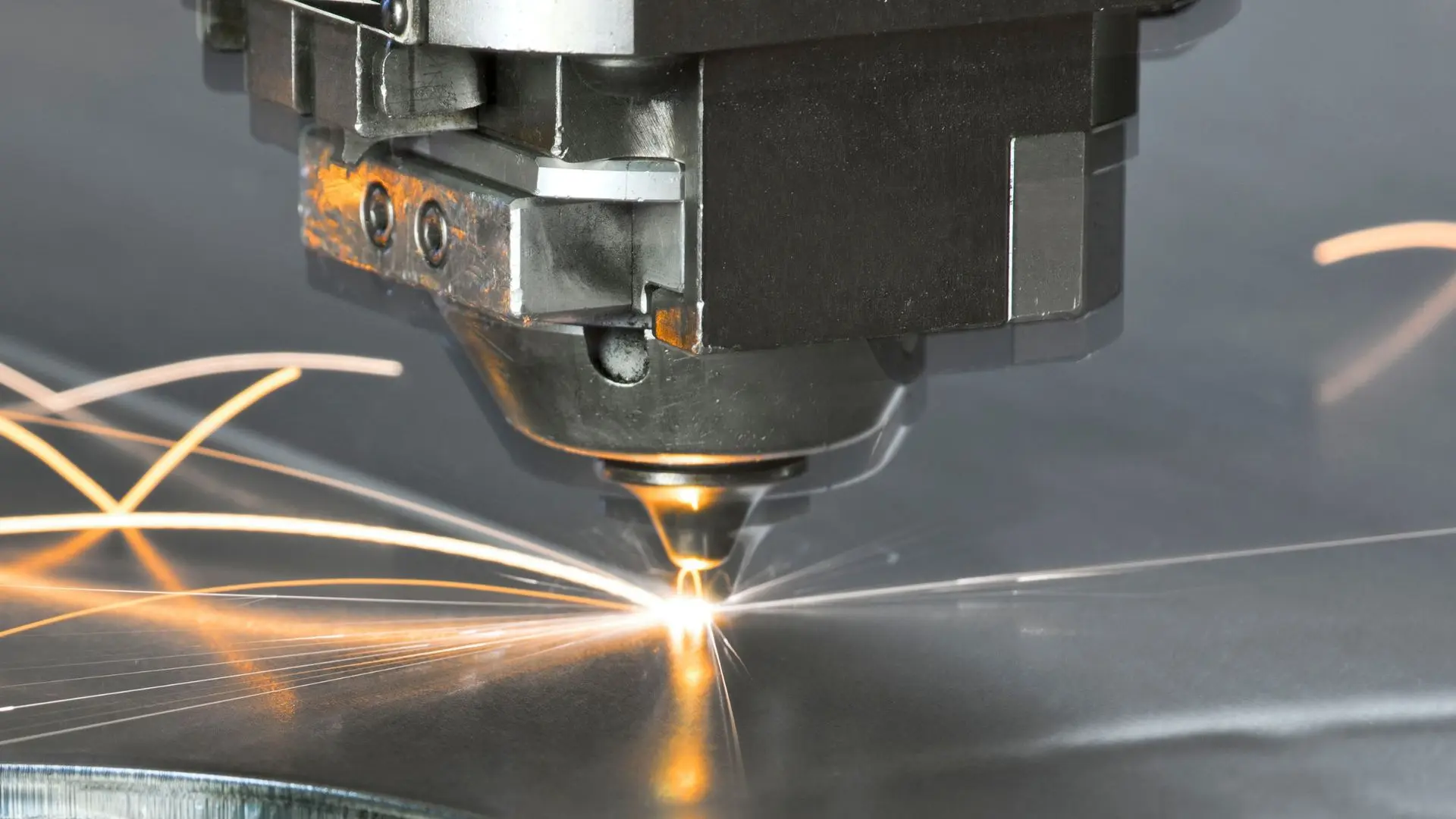

Embrace the eco-conscious revolution of laser paint removal, an ingenious technique designed to strip metal surfaces of paint without compromising their integrity.

Cost-Effective Laser Paint Removal with LaserBlast

Laser paint removal is versatile in its applications, catering to a range of metals, including steel, aluminum, and copper, and tackling coatings such as powder, e-coating, and phosphate.

Whether employing a single-mode fiber laser to texturize the base metal or a multimode fiber laser for rapid cleaning, this process offers unparalleled efficiency and sustainability in paint removal and surface restoration.

The LaserBlast™ System from Allied Scientific Pro is the optimal solution for paint removal and cleaning projects. Our cost-effective and eco-friendly laser paint removal systems require minimal preparation time and incur no disposal costs, making them a highly efficient, time-saving solution.

Our Models - LaserBlast Product Lineup

Laserblast 100W

- 100 Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 200W

- 200Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 300W

- 300Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 500W

- 500Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 2000W

- 2000Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Laserblast 1000W

- 1000Watts

- Long Lifetime, Ultra-robust

- Presets easy to use for different surface

- Controllable laser beam shape

Discover the Benefits of Allied Scientific Pro Laser Paint Removal

- User-Friendly with No Additional Gear Needed: The LaserBlast™ System is user-friendly and requires no dangerous projectiles or additional protective gear. The laser coating removal process is controlled through a computer, making it easy to use. Laser ablation is a relatively low-noise operation and does not damage the underlying substrate.

- Low Carbon Footprint: Our laser cleaning system is an eco-friendly solution to remove paint using a laser beam that does not require hazardous chemicals or blast media. The system only requires electricity, making it a clean technology with a low carbon footprint.

- AI-Driven for Intelligent Settings: The LaserBlast™ System is a digitally controlled AI-driven system with intelligent settings. The system also allows for on-the-fly changes and can be robotized to increase efficiency and accuracy.

- Faster and More Efficient Paint Removal: Our laser paint removal works without additional gear and incurs no disposal costs, making it a significant cost savings over other paint removal methods.

- Safe and User-Friendly Operation: Our machines are user-friendly and eliminate the risk of dangerous projectiles. The laser energy is also quiet and controlled by an intelligent computerized system, providing a user-friendly experience.

- Ideal for Various Industries and Applications: Our laser paint removal machines are versatile and suitable for aerospace, automotive, and conservation & restoration applications, making them an effective solution for paint or coating removal. Also, the absence of chemicals or blast media makes them an ideal solution for industrial applications where hazardous materials are a concern.

Convenience

COST-SAVING

- Minimal preparation time

- No disposal cost

- No additional gear needed

- Time-saving

USER FRIENDLY

- No dangerous projectiles

- Computer-controlled

- No protective wear required

- Low noise operation

CLEANTECH

- Eco friendly

- No chemicals

- No blast media

- Consumes only electricity

AI-DRIVEN

- Fully digital controlled

- Intelligent setting

- Setting on the fly

- Robotization available

Click Here to Lease our Laserblast Cleaning System

LASER AERO

This high-powered laser cleaning system is ideal for surface cleaning and paint removal applications in the aerospace and automotive industry. Save time with laser rust removal, paint stripping, and mold cleaning for preparing surfaces for painting. It's also more environmentally friendly than traditional abrasive cleaning technology.

- Scanner Head: Software allows for many types of scans: round, linear, and square. The laser beam can adapt to various surface shapes.

- Estimated Lifetime Expectancy: 10 years

- Computer: Robust, easy-to-use computer or tablet gives full control over cleaning

- Software: EZClean software included

- 3 presets cleaning process included

LASER BLAST

A handheld laser cleaning solution ideal for grease cleaning, coating removal, nuclear decontamination, and pre-treatment or preparing surfaces for welding. A great alternative to traditional surface preparation techniques.

- Power: 100Watts

- Beam Size: 10 - 100 mm

- Estimated Life Expectancy: 60K hours

- Fume Extraction System: vacuum

- Manual Control: handheld

LASER ART

An ideal laser surface cleaner for building restoration projects; compatible with stone, metals, wood, and many other materials. Gentle enough for art, sculpture, and classic car restoration projects. Also, laser paint removal, such as removing graffiti, is a time-saving and efficient alternative to sandblasting or other abrasive cleaning methods.

- Scanner Head: Software allows for various scans: round, linear, or square. The laser light beam can be adapted to different shapes of surfaces.

- Estimate Lifetime Expectancy: 10 years

- Computer: Robust and easy-to-use computer or tablet gives full control over the laser cleaning process

- Software: EZClean software included

- 3 preset laser cleaning processes included

Laser-Cleaning Systems

Laser Paint Removal | Industries & Applications

- Automotive Industry: part cleaning before the coating process, laser rust removal for refurbishment or renovation.

- Aerospace industry: removing paint layers from fuselages, surface cleaning, and rotor blade cleaning.

- Building Renovation & Conservation: mold cleaning, paint removal, stone and metal cleaning.

- Industrial: lead-based paint removal from machinery or plant and stripping old marine coatings from vessels.

Why Choose ASP Industrial Laser Cleaning Systems?

Features

- ASP's LaserBlast Cleaning systems offer a wide range of power options, including 100W, 200W, 300W, 500W, 1000W, and 2000W, allowing users to select the most suitable system for their needs

- Each system utilizes advanced photonics, mechanics, electronics, robotics, imaging, spectroscopy, and AI technologies in its design, and is highly effective at surface treatment and cleaning without using any chemicals or blast media.

- The digitally controlled system features an intuitive user interface that enables users to start cleaning instantly.

Benefits

- Cost-saving - With no additional chemicals or blast media required, ASP's Laser process helps reduce costs associated with traditional cleaning methods.

- Eco-friendly - No chemical pollutants are released during the laser cleaning process, making it one of the most environmentally friendly solutions available today.

- User-friendly – The interface and controls make it easy to operate and achieve faster cleaning than with traditional methods.

Experienced Technical Team

Our experienced technical experts are ready to take on your cleaning challenges. Our multi-disciplinary staff specializes in engineering solutions incorporating photonics, spectroscopy, mechanics, electronics, robotics, AI, and computer programming.

Our expertise enables us to develop innovative laser cleaning machines and provide a cost-effective, user-friendly solution for all your cleaning needs.

So why wait? Get the job done right with ASP's LaserBlast Cleaning System.

Learn More About Laser Cleaning

Explore our latest articles and guides on laser cleaning technology, applications, and industry use cases.

How to Choose a Laser Cleaning Machine

Understand the key factors—laser power, material, and precision—to select the right system for your needs.

Laser Cleaning Applications: All Uses & Industries

Explore how laser cleaning is used in automotive, aerospace, cultural heritage, and manufacturing.

Environmental Evaluation of Abrasive Blasting

Compare traditional abrasive blasting with modern, eco-friendly laser cleaning methods.

Lead and zinc-based paint stripping using laser technology

Efficacy and cost benefits of laser technology in paint stripping compared to traditional methods.

Laser Cleaning Advantages: All 20 Benefits

From precission and efficiency to eco-friendliness and versatility compared to other methods.

Laser removal of epoxy coatings on stainless steel using beam scanning patterns as control parameters

How controlling the shape of marking patterns can achieve more uniform coating removal.

Nuclear Decontamination by Laser for Decommissioning

Advantages and challenges of laser cleaning technology in nuclear decontamination

Application of Laser Cleaning Prior to Laser Welding of Aluminum Alloys

Reduction of porosity levels in aluminum alloy laser welding by laser cleaning before welding.

Laser Cleaning Materials: Ultimate Guide on All Supported Ones

A complete list of materials and the suitable types of laser cleaning applications for them

SOME OF OUR VALUED CLIENTS & PARTNERS

we work in close partnership with our clients to ensure that all design needs are met in a timely manner. Our specialists and engineers work closely together to develop tailor-made solutions that meet the industry evolving needs.